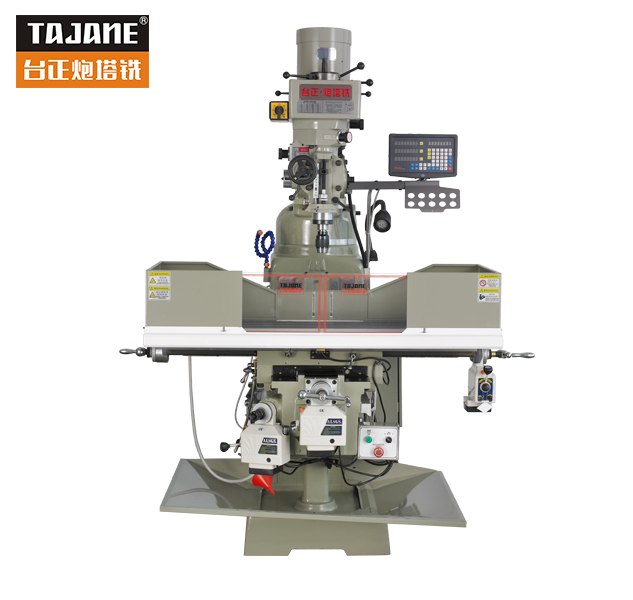

High Precision CNC Processing Center for Advanced Manufacturing

By:Admin

The new Cnc Processing Center is designed to deliver high-speed, high-precision machining capabilities, making it ideal for a wide range of applications across various industries. With its intelligent control system and advanced software, the center offers unmatched accuracy and consistency, ensuring superior quality output for every project. Whether it's milling, drilling, cutting, or engraving, this new processing center is capable of handling complex tasks with ease and precision.

One of the key highlights of the new processing center is its enhanced automation capabilities, which significantly reduce manual intervention and human error, leading to greater efficiency and productivity. The advanced robotic arm and tool changing system allow for seamless operation and minimal downtime, making it an ideal solution for high-volume production requirements.

In addition, the center's modular design and customizable features enable it to adapt to specific manufacturing needs, offering flexibility and scalability for diverse production requirements. This versatility makes it an ideal choice for small-scale workshops as well as large-scale industrial operations, catering to a wide spectrum of manufacturing needs.

Furthermore, the Cnc Processing Center is equipped with advanced safety features and environmental controls, ensuring a safe and sustainable working environment. With built-in sensors and monitoring systems, the center complies with the highest industry standards for workplace safety and environmental protection, making it a responsible and reliable choice for businesses.

"We are thrilled to introduce our new Cnc Processing Center, which represents a significant milestone in our commitment to delivering cutting-edge machining solutions," said [Company Name] spokesperson. "With its advanced capabilities and unmatched performance, we believe this center will empower manufacturers to elevate their production processes and achieve greater levels of precision and efficiency."

The launch of the new Cnc Processing Center underscores [Company Name]'s ongoing dedication to innovation and technological advancement in the field of CNC machining solutions. With a legacy of excellence and a proven track record of delivering dependable products, the company continues to push the boundaries of what's possible in modern manufacturing.

"We are proud to build on our legacy of excellence with the introduction of this new processing center, which reflects our unwavering commitment to driving innovation and meeting the evolving needs of the industry," added the spokesperson. "We are confident that this center will set new benchmarks for precision, efficiency, and reliability, empowering businesses to achieve their manufacturing goals with confidence."

As the manufacturing industry continues to evolve and demand higher levels of precision and efficiency, the new Cnc Processing Center from [Company Name] is poised to make a significant impact. Its innovative features, advanced technology, and unparalleled performance position it as a game-changer in the world of CNC machining, promising to elevate the capabilities of businesses and industries across the globe.

Company News & Blog

Quality CNC Slant Bed Lathe Supplier in China

China CNC Slant Bed Lathe Supplier Leads the Way in Precision EngineeringIn the world of manufacturing, precision and efficiency are key factors in producing high-quality products. This is where a leading supplier of CNC slant bed lathes in China has been making a significant impact. The company, known for its cutting-edge technology and dedication to innovation, has been at the forefront of the industry, providing top-of-the-line machinery to businesses worldwide.With a focus on quality and reliability, this CNC slant bed lathe supplier has gained a reputation for excellence in the manufacturing sector. Their machines are known for their precision engineering, advanced control systems, and high-speed capabilities, making them ideal for a wide range of applications, from automotive and aerospace to medical and electronics.One of the key factors that set this supplier apart from others in the industry is their commitment to continuous improvement and innovation. They invest heavily in research and development, constantly striving to enhance the performance and capabilities of their CNC slant bed lathes. This dedication to innovation has led to the development of cutting-edge features and technologies, ensuring that their machines remain at the forefront of the industry.Furthermore, the company's strict quality control measures and rigorous testing procedures ensure that each CNC slant bed lathe that leaves their facility meets the highest standards of performance and reliability. This attention to detail and commitment to quality has earned them the trust and confidence of their customers, who rely on their machinery to deliver exceptional results consistently.In addition to their advanced technology and superior quality, this CNC slant bed lathe supplier also offers comprehensive customer support and service. Their team of skilled technicians and engineers provide expert guidance and assistance to customers, ensuring that they are able to maximize the potential of their machinery and achieve optimal results in their manufacturing processes.Moreover, the company's commitment to environmental sustainability is evident in their efforts to develop energy-efficient and eco-friendly machinery. By incorporating innovative technologies and environmentally conscious practices into their manufacturing processes, they contribute to a greener and more sustainable future for the industry.As a leading supplier of CNC slant bed lathes in China, this company has established a strong presence in the global market, with a wide network of distributors and partners across the world. Their commitment to excellence, coupled with their ability to adapt to the evolving needs of the industry, has positioned them as a trusted and reliable partner for businesses seeking cutting-edge solutions for their manufacturing operations.Looking ahead, this CNC slant bed lathe supplier is poised to continue leading the way in precision engineering, innovation, and excellence in the manufacturing sector. With a focus on advancing technology, improving efficiency, and exceeding customer expectations, they are set to remain at the forefront of the industry, shaping the future of manufacturing with their state-of-the-art machinery and unwavering commitment to quality.In conclusion, this leading supplier of CNC slant bed lathes in China has set a high standard for precision engineering and innovation in the manufacturing sector. With their advanced technology, superior quality, and dedication to customer satisfaction, they have earned a reputation as a trusted partner for businesses seeking top-of-the-line machinery for their manufacturing operations. As they continue to push the boundaries of technology and excellence, they are well-positioned to remain at the forefront of the industry, driving innovation and shaping the future of manufacturing.

High Precision Large Horizontal Milling Machine for Heavy-duty Machining

Large Horizontal Milling Machine Revolutionizes Manufacturing at {}The manufacturing industry is constantly evolving with new technologies and processes. One key innovation that is transforming the industry is the large horizontal milling machine, which has the capability to precision-mill large components for a wide range of industries. One company that has fully embraced this technology is {}, a leading manufacturer of heavy-duty equipment.The large horizontal milling machine, which is the centerpiece of {}, has the ability to handle extremely large and heavy workpieces with unparalleled precision and efficiency. This state-of-the-art machine is equipped with advanced features such as multiple axis control, automatic tool changer, and high-speed spindle, making it capable of performing complex machining operations with ease.One of the key benefits of the large horizontal milling machine is its ability to produce large components with exceptional accuracy and surface finish. This is essential for industries such as aerospace, automotive, and energy, where precision and quality are critical to the performance and safety of the end products. With the large horizontal milling machine, {} is able to meet the highest standards and specifications of its customers, ensuring that their products are of the highest quality.Furthermore, the large horizontal milling machine has significantly improved the efficiency and productivity of {}, allowing the company to take on larger and more complex projects. With its large work envelope and high-speed capabilities, the machine is able to reduce production time and costs, while maintaining superior quality. This has allowed {} to remain competitive in the market and continue to expand its capabilities and offerings to its customers.In addition to its technical capabilities, {} has also invested in training its workforce to operate and program the large horizontal milling machine effectively. This has allowed the company to maximize the potential of the machine and fully utilize its advanced features, leading to improved performance and results. Furthermore, {} has established a dedicated engineering team that works closely with customers to develop custom solutions using the large horizontal milling machine, providing added value and innovation to its services.{} is proud to be at the forefront of the manufacturing industry, leading the way with its investment in advanced technology such as the large horizontal milling machine. With this cutting-edge equipment, the company is able to offer a wide range of machining services, including milling, drilling, boring, and tapping, for a variety of materials such as steel, aluminum, and composites. This versatility has made {} a preferred partner for many leading manufacturers in the industry.Looking ahead, {} is committed to continuously investing in the latest technologies and equipment to stay ahead of the competition and meet the evolving needs of its customers. The large horizontal milling machine is just one example of the company's dedication to innovation and excellence in manufacturing. With its advanced capabilities and skilled workforce, {} is well-positioned to continue delivering high-quality, precision-machined components for a wide range of industries, ensuring its continued success and leadership in the market.In conclusion, the large horizontal milling machine has revolutionized manufacturing at {}. With its unparalleled precision, efficiency, and versatility, the machine has enabled the company to produce large components with exceptional quality and speed, while remaining competitive in the market. {}'s investment in this advanced technology highlights its commitment to innovation and excellence, and its dedication to meeting the evolving needs of its customers. As the manufacturing industry continues to evolve, {} is well-prepared to lead the way with its cutting-edge capabilities and expertise in precision machining.

Benchtop Machining Center: Enhancing Precision and Efficiency

Title: Innovation and Precision: New Benchtop Machining Center Revolutionizes ManufacturingIntroduction:In today's rapidly evolving manufacturing landscape, businesses are constantly seeking innovative solutions that enhance efficiency, precision, and productivity. With this in mind, a renowned company announces the launch of their groundbreaking Benchtop Machining Center. Leveraging cutting-edge technology and an unwavering commitment to quality, this state-of-the-art machine is set to revolutionize the manufacturing sector. Combining speed, accuracy, and versatility, the Benchtop Machining Center promises to be a game-changer in the industry, empowering businesses with the tools they need to succeed in an increasingly competitive market.[Company Name], born out of years of experience and a dedication to excellence, has paved the way for advanced machining technology. Their ethos centers on delivering tools that exceed customer expectations and enhance manufacturing processes across a wide range of industries. With their Benchtop Machining Center, [Company Name] aims to equip businesses with a transformative solution that accelerates productivity, increases accuracy, and reduces downtime, all while maintaining unmatched levels of quality.Streamlining Manufacturing Processes:The Benchtop Machining Center boasts a wide array of features meticulously designed to optimize manufacturing processes. One of its standout attributes is its ability to perform multiple operations simultaneously, reducing the need for manual intervention and significantly speeding up production cycles. Combining milling, drilling, and precision turning in a single unit, this state-of-the-art machine ensures maximum versatility and cost-efficiency for businesses of all sizes.Unmatched Precision and Accuracy:Precision is the foundation of manufacturing excellence, and the Benchtop Machining Center offers unmatched accuracy and repeatability. Equipped with advanced computer numerical control (CNC) systems, the machine ensures that every cut, drill, or turn is executed with meticulous precision, resulting in consistently high-quality parts. This level of accuracy not only enhances product quality but also minimizes material waste, leading to significant cost savings for manufacturers.Intuitive User Interface:Recognizing the importance of user-friendly interfaces in optimizing productivity, [Company Name] has developed an intuitive control system for the Benchtop Machining Center. Featuring a user-friendly touchscreen panel, operators can effortlessly navigate through the machine's various functions, enabling seamless operations and reducing potential human errors. Additionally, the control system includes built-in safety features that prioritize operator well-being, further enhancing the overall user experience.Quality Engineering:The Benchtop Machining Center is the result of meticulous engineering and rigorous quality control. Employing high-quality materials and cutting-edge manufacturing techniques, each unit is built to withstand demanding operational environments. Robustness and reliability are key attributes of this machine, ensuring that manufacturers can rely on the Benchtop Machining Center for consistently outstanding performance.Versatility and Adaptability:Recognizing the diverse needs of modern manufacturers across industries, the Benchtop Machining Center offers maximum versatility and adaptability. With its modular design, the machine can be easily customized and upgraded to meet evolving manufacturing requirements. From small fabrication workshops to large-scale manufacturing facilities, the Benchtop Machining Center can be tailored to fit varying demands, ensuring that the investment remains future-proof.Conclusion:As the manufacturing sector continues to evolve and innovate, the Benchtop Machining Center introduces a new era of precision, speed, and versatility. [Company Name] intends to redefine manufacturing standards by empowering businesses with this state-of-the-art machine. With its comprehensive range of features, unparalleled precision, and user-friendly interface, the Benchtop Machining Center is poised to catalyze productivity and efficiency for manufacturers worldwide. In an increasingly competitive market, this innovative solution will undoubtedly set new benchmarks for manufacturing excellence, solidifying [Company Name]'s position as a leader in the industry.

Leading Manufacturer of Keyway Milling in China

China Keyway Milling Manufacturer has been making waves in the machining industry with its innovative technologies and high-quality products. As a leading player in the manufacturing and distribution of keyway milling machines, the company has established a solid reputation for its dedication to excellence and customer satisfaction.Founded in 2005, China Keyway Milling Manufacturer has quickly risen to prominence in the industry, thanks to its commitment to delivering cutting-edge solutions for keyway milling processes. The company's state-of-the-art facilities and advanced equipment enable it to produce a wide range of milling machines that meet the highest standards of quality and performance.One of China Keyway Milling Manufacturer's key strengths lies in its ability to customize products to meet the unique needs and specifications of its clients. The company's team of skilled engineers and technicians work closely with customers to design and develop bespoke milling solutions that are tailored to their specific requirements. This level of flexibility and attention to detail has earned China Keyway Milling Manufacturer a loyal and ever-growing customer base, both domestically and internationally.In addition to its focus on product customization, China Keyway Milling Manufacturer also places a strong emphasis on continuous innovation and improvement. The company invests heavily in research and development to stay ahead of market trends and technological advancements, ensuring that its product line remains at the forefront of the industry. By leveraging the latest manufacturing techniques and incorporating cutting-edge technologies, China Keyway Milling Manufacturer continues to set new benchmarks for quality and reliability in keyway milling equipment.Furthermore, China Keyway Milling Manufacturer is renowned for its unwavering commitment to quality control and adherence to strict industry standards. The company's manufacturing processes are subjected to rigorous inspections and testing protocols to guarantee that every product that leaves its facilities is flawless and dependable. This dedication to quality assurance has earned China Keyway Milling Manufacturer numerous certifications and accolades, cementing its position as a trusted and reputable provider of milling solutions.Despite its rapid growth and success, China Keyway Milling Manufacturer remains firmly dedicated to sustainability and environmental responsibility. The company is continually exploring eco-friendly manufacturing practices and technologies to minimize its ecological footprint and contribute to a greener, more sustainable future. By integrating sustainable initiatives into its operations, China Keyway Milling Manufacturer not only demonstrates its corporate citizenship but also sets an example for the industry as a whole.Looking ahead, China Keyway Milling Manufacturer is poised to continue its trajectory of growth and expansion, driven by its steadfast commitment to excellence and innovation. The company's relentless pursuit of customer satisfaction, paired with its uncompromising standards of quality and performance, positions it as a formidable force in the global keyway milling market.In conclusion, China Keyway Milling Manufacturer's remarkable success is a testament to its unwavering dedication to delivering top-tier milling solutions to its clients. Through its focus on customization, innovation, quality control, and sustainability, the company has carved out a distinct niche in the industry and solidified its standing as a trailblazer. As it continues to push the boundaries of what is achievable in keyway milling, China Keyway Milling Manufacturer is set to remain an indispensable partner for businesses seeking superior machining solutions.

High-quality Knee Milling Machine Factory: The Latest News

Jet Knee Milling Machine Factory, a leading manufacturer of innovative and high-quality milling machines, has recently expanded its production capacity to meet the growing demand for its products.The company, which was established in 1980, has quickly become a trusted name in the milling machine industry, thanks to its commitment to providing reliable, efficient, and precise machines for a wide range of applications. With its state-of-the-art facilities and a team of experienced engineers and technicians, Jet Knee Milling Machine Factory has been able to consistently deliver top-notch products to its customers.The recent expansion of the production capacity comes in response to the increasing demand for Jet Knee's milling machines, both domestically and internationally. The company has seen a steady rise in orders from industries such as automotive, aerospace, defense, and general manufacturing, among others. In order to keep up with this growing demand, Jet Knee has made significant investments in its manufacturing facilities, including the acquisition of new equipment and the hiring of additional staff."We are thrilled to announce the expansion of our production capacity," said the CEO of Jet Knee Milling Machine Factory. "This is a testament to our commitment to meeting the needs of our customers and ensuring that they have access to the best milling machines on the market. With our increased capacity, we are well-positioned to serve a wider range of industries and continue to provide innovative solutions for their machining needs."Jet Knee's milling machines are known for their precision, durability, and versatility. The company offers a diverse range of models, including vertical milling machines, horizontal milling machines, and universal milling machines, each designed to meet the specific requirements of different applications. Additionally, Jet Knee provides customization options, allowing customers to tailor the machines to their exact specifications.The expanded production capacity will enable Jet Knee to fulfill large orders in a timely manner while maintaining the high standards of quality that the company is known for. By streamlining its manufacturing processes and implementing efficient production techniques, Jet Knee is confident that it will be able to meet the increasing demand without compromising on the integrity of its products.In addition to expanding its manufacturing capabilities, Jet Knee is also focused on enhancing its customer service and support. The company has a dedicated team of customer service professionals who are readily available to assist clients with technical inquiries, installation, maintenance, and any other service-related needs. Jet Knee is committed to building long-lasting relationships with its customers and ensuring that they receive the necessary support throughout the lifespan of their milling machines.As Jet Knee Milling Machine Factory continues to grow, it remains committed to staying at the forefront of innovation in the milling machine industry. The company continuously invests in research and development to refine its existing products and develop new solutions that can address the evolving needs of its customers. By staying ahead of technological advancements and market trends, Jet Knee aims to remain a leader in the milling machine industry for years to come.With its enhanced production capacity, unwavering dedication to quality, and focus on customer satisfaction, Jet Knee Milling Machine Factory is poised to continue its success and solidify its position as a premier manufacturer of milling machines. The company looks forward to serving its existing customers as well as reaching new markets with its expanded capabilities and comprehensive product offerings.

Precision Gantry Machining for High-Quality Results

Innovative Gantry Machining Technology Revolutionizes Manufacturing IndustryThe manufacturing industry is witnessing a revolution with the introduction of cutting-edge Gantry Machining technology by a leading company in the field of precision engineering and manufacturing. The advanced Gantry Machining technology has been hailed as a game-changer in the industry, offering unparalleled precision, efficiency, and productivity in the manufacturing process.The Gantry Machining technology, developed and pioneered by the company, represents a significant leap forward in the field of machining and manufacturing. It is a testament to the company's commitment to innovation and excellence, as well as its relentless pursuit of pushing the boundaries of what is possible in manufacturing.The technology features a state-of-the-art Gantry Machining system that is equipped with advanced CNC controls and high-speed capabilities. This allows for the machining of complex and intricate parts with unmatched accuracy and precision. The system also boasts a large work envelope, enabling it to handle workpieces of varying sizes and shapes, thus providing unparalleled flexibility and versatility in manufacturing.One of the key advantages of the Gantry Machining technology lies in its ability to significantly reduce lead times and production costs while maintaining the highest quality standards. This is achieved through the system's high-speed machining capabilities, which enable the rapid and efficient production of parts and components without compromising on quality.Furthermore, the Gantry Machining technology is designed to optimize productivity and efficiency in the manufacturing process. Its advanced automation and robotic capabilities enable the system to operate continuously and autonomously, thereby maximizing the utilization of resources and minimizing downtime.In addition to its technical prowess, the Gantry Machining technology is also characterized by its user-friendly interface and intuitive controls. This allows operators to easily program and monitor the machining process, ensuring seamless and efficient operation.The implementation of the Gantry Machining technology is set to have a transformative impact on the manufacturing industry. Its ability to deliver high-quality, precision-engineered components at an accelerated pace will facilitate the development of innovative products across various sectors, from aerospace and automotive to medical device manufacturing.Moreover, the technology's potential to streamline production processes and drive operational efficiencies will undoubtedly yield significant cost savings for manufacturers, thus enhancing their competitiveness in the global market.Through the introduction of this revolutionary Gantry Machining technology, the company has once again established itself as a pioneer and leader in the manufacturing industry. Its innovative approach to engineering and manufacturing has set a new benchmark for quality, precision, and efficiency, thereby reshaping the future of manufacturing.As the industry continues to evolve and embrace advanced technologies, the Gantry Machining technology is poised to play a pivotal role in driving the next phase of industrial innovation, and the company is at the forefront of this transformative movement.In conclusion, the introduction of the Gantry Machining technology by the company represents a watershed moment in the manufacturing industry. Its unparalleled precision, efficiency, and productivity capabilities are set to redefine the standards of manufacturing, and propel the industry into the future. With this revolutionary technology, the company has once again demonstrated its commitment to pushing the boundaries of what is possible in engineering and manufacturing, and cemented its position as a driving force of innovation in the industry.

Large Vertical Turning Center Factory in China: What You Need to Know

China Large Vertical Turning Center Factory, a leading manufacturer of CNC machine tools, recently announced the opening of a new state-of-the-art production facility. This new factory is dedicated to the production of large vertical turning centers, which are essential for the machining of large and heavy workpieces. The facility is equipped with the latest technology and is expected to significantly increase the company's production capacity.The new factory is strategically located in a manufacturing hub, which allows for easy access to raw materials and transportation. The facility covers a vast area, with separate sections for manufacturing, assembly, quality control, and testing. The company has invested heavily in advanced machinery and equipment to ensure that the production process is efficient and of the highest quality.Large vertical turning centers are crucial for industries such as aerospace, automotive, energy, and heavy machinery. These machines are used for turning, milling, and drilling large workpieces with high precision and accuracy. The demand for large vertical turning centers has been steadily increasing, and China Large Vertical Turning Center Factory has recognized the opportunity to expand its production capacity to meet this growing demand.The company's commitment to innovation and continuous improvement is reflected in the design and layout of the new factory. The production process is highly automated, with a focus on streamlining operations and maximizing efficiency. This approach not only ensures high-quality products but also reduces lead times, allowing the company to better serve its customers.China Large Vertical Turning Center Factory has a strong focus on quality control and testing. The new facility is equipped with advanced testing equipment to ensure that every machine meets the highest standards of accuracy and performance. Additionally, the company has implemented strict quality control processes at every stage of the production process to identify and address any issues proactively.Moreover, the company has a team of highly skilled engineers and technicians who are responsible for the design, development, and production of the large vertical turning centers. These professionals have undergone extensive training and possess a wealth of experience in the field of CNC machine tools. Their expertise and dedication are instrumental in ensuring that the products manufactured at the new facility are of the highest quality.Furthermore, China Large Vertical Turning Center Factory is committed to environmental sustainability. The new facility has been designed with eco-friendly features, such as energy-efficient machinery and waste management systems. The company understands the importance of minimizing its environmental impact and is constantly seeking ways to reduce its carbon footprint.The opening of the new factory is a significant milestone for China Large Vertical Turning Center Factory. It represents the company's dedication to growth and innovation in the field of CNC machine tools. By increasing its production capacity for large vertical turning centers, the company aims to better serve its customers and meet the growing demand for these essential machines.In conclusion, the opening of the new state-of-the-art production facility is a testament to China Large Vertical Turning Center Factory's commitment to excellence and innovation. The company's investment in advanced technology and infrastructure will undoubtedly strengthen its position as a leading manufacturer of CNC machine tools. With the increased production capacity, the company is well-positioned to meet the growing demand for large vertical turning centers and continue to serve its customers with high-quality products.

Top Large Machining Center Manufacturers in China

China's large machining center industry has been witnessing rapid development in recent years, with an increasing number of manufacturers emerging in the market. The demand for large machining centers has been growing steadily, driven by the increasing demand for high-precision machining in industries such as aerospace, automotive, and mold making.One of the prominent manufacturers in this industry is a leading Chinese company that specializes in the development and production of large machining centers. With a strong focus on innovation and technological advancement, the company has gained a reputation for producing high-quality, reliable, and efficient machining centers that meet the diverse needs of its customers.Established in [year], the company has grown to become a key player in the Chinese machining industry, catering to a wide range of industries including aerospace, automotive, energy, and heavy machinery. The company's machining centers are known for their high precision, efficiency, and reliability, making them a preferred choice for many customers who seek to optimize their machining processes.The company's success can be attributed to its strong commitment to research and development. With a dedicated team of engineers and technicians, the company invests heavily in the development of new technologies and innovative solutions to meet the evolving needs of its customers. This commitment to innovation has enabled the company to stay ahead of the competition and maintain its position as a leading manufacturer of large machining centers in China.In addition to its technological prowess, the company also places great importance on quality control and customer satisfaction. The company's state-of-the-art production facilities are equipped with advanced quality control systems to ensure that every machining center that leaves its factory meets the highest standards of quality and performance. Furthermore, the company has a dedicated team of customer support professionals who provide comprehensive after-sales support to ensure that customers get the most out of their machining centers.The company's strong emphasis on innovation, quality, and customer satisfaction has earned it a solid reputation both domestically and internationally. Its machining centers have been exported to numerous countries around the world, earning the company a strong presence in the global marketplace. With a commitment to excellence and a dedication to meeting the needs of its customers, the company is well-positioned to continue its growth and success in the large machining center industry.In conclusion, China's large machining center industry is flourishing, driven by the increasing demand for high-precision machining in various industries. The company's commitment to innovation, quality, and customer satisfaction has made it a key player in the industry, with a strong presence both domestically and internationally. With its dedication to research and development, advanced production facilities, and comprehensive customer support, the company is well-equipped to continue meeting the diverse needs of its customers and contribute to the growth and advancement of the large machining center industry in China and beyond.

Top Supplier of Manual Knee Milling Machines for Your Business Needs

[Insert Company Logo]Manual Knee Milling Machine Supplier, [Company Name], Continues to Lead the Industry with Innovative Products and Exceptional Service[City, State] – As the manufacturing industry continues to evolve, the demand for high-quality machinery has never been greater. For [Company Name], a leading supplier of manual knee milling machines, meeting this demand has been their primary focus for over [number] years. With a commitment to innovation, exceptional service, and unparalleled expertise, [Company Name] has established itself as a trusted partner for businesses across a wide range of industries.Since its inception in [year], [Company Name] has been dedicated to providing the highest quality manual knee milling machines to its customers. With a focus on precision engineering and advanced technology, the company has continually pushed the boundaries of what is possible in the field of milling machinery. By employing a team of skilled engineers and technicians, [Company Name] has been able to develop and manufacture a wide range of manual knee milling machines that are known for their reliability, accuracy, and performance.In addition to the company's commitment to product excellence, [Company Name] is also known for its exceptional customer service and support. With a network of knowledgeable sales representatives and a dedicated customer service team, the company is able to provide its customers with the guidance and support they need to make informed decisions about their machinery purchases. Moreover, [Company Name] offers comprehensive training and technical support to ensure that its customers are able to fully maximize the potential of their manual knee milling machines.One of the key factors that have set [Company Name] apart from its competitors is its dedication to innovation. The company is constantly researching and developing new technologies and manufacturing processes to improve the performance and efficiency of its manual knee milling machines. By staying at the forefront of industry trends and investing in the latest advancements in technology, [Company Name] has been able to consistently deliver cutting-edge solutions to its customers.As part of its commitment to innovation, [Company Name] has recently introduced a new line of manual knee milling machines that are set to revolutionize the industry. These new machines feature state-of-the-art controls and automation systems that enable users to achieve unprecedented levels of precision and productivity. With a focus on user-friendly design and intuitive operation, these new machines are expected to set a new standard for manual knee milling machines.In addition to its dedication to innovation and product excellence, [Company Name] is also deeply committed to sustainability and environmental responsibility. The company has implemented strict sustainability practices in its manufacturing processes, ensuring that its operations have minimal impact on the environment. By using energy-efficient technologies and sustainable materials, [Company Name] is able to reduce its carbon footprint and contribute to a cleaner, healthier planet.Looking ahead, [Company Name] remains dedicated to its mission of providing the highest quality manual knee milling machines to its customers. With a focus on innovation, exceptional service, and environmental responsibility, the company is well-positioned to continue leading the industry for years to come.For more information about [Company Name] and its range of manual knee milling machines, please visit [company website] or contact [contact information].Media Contact:[Your Name][Company Name][Phone Number][Email Address][Website]

Unlocking the Full Potential of 3-Axis CNC Vertical Milling Machines

Title: High-Precision 3 Axis CNC Vertical Milling Machine Boosts Manufacturing EfficiencyIntroduction:In the ever-evolving landscape of manufacturing, efficiency and precision are key factors determining success. A prominent player in this realm, [Company Name], has recently introduced their state-of-the-art 3 Axis CNC Vertical Milling Machine. This cutting-edge machinery, aptly designed to remove material with unfailing precision, is set to revolutionize the manufacturing industry.Revolutionizing Precision:The 3 Axis CNC Vertical Milling Machine employs the latest advancements in technology to enhance precision manufacturing. Equipped with the latest servo motors and an innovative control system, the machine enables highly accurate and repeatable machining operations. The three-axis configuration allows for simultaneous movement of the X, Y, and Z axes, ensuring versatile and complex machining capabilities.Unparalleled Efficiency:[Company Name]'s 3 Axis CNC Vertical Milling Machine boasts a rigid and stable construction, providing the foundation for superior precision and efficiency. With advanced positioning techniques and rapid deployment capabilities, this machinery significantly reduces production time and enhances overall efficiency. From small-scale prototype production to mass production of intricate components, this machine is tailored to meet the diverse needs of manufacturers across various industries.Versatile Application:The versatility of the 3 Axis CNC Vertical Milling Machine makes it suitable for a wide range of applications. From aerospace and automotive sectors to medical and electronics industries, this equipment accommodates the machining needs of both large-scale manufacturers and small businesses. Its exceptional flexibility enables the creation of intricate parts, molds, prototypes, and custom components, meeting the unique demands of each sector.Seamless Integration with CAD/CAM Software:[Company Name] has seamlessly integrated the 3 Axis CNC Vertical Milling Machine with cutting-edge CAD/CAM software. This integration allows for automatic generation of machine programs, eliminating the need for manual input and minimizing the likelihood of errors. Additionally, the software enables efficient toolpath optimization, reducing material waste and enhancing productivity. Manufacturers can effortlessly convert their design ideas into tangible products with the help of this powerful combination.User-Friendly Interface:Understanding the importance of user experience, [Company Name] has designed the 3 Axis CNC Vertical Milling Machine with an intuitive interface. The user-friendly control panel simplifies the machining process, allowing operators to effortlessly program the machine, monitor operations, and make real-time adjustments. This ensures a smooth and seamless workflow, enabling operators to focus on other critical aspects of production. The machine's ergonomic design also prioritizes operator comfort and safety.Commitment to Sustainability:As environmental concerns grow, the manufacturing industry is seeking more sustainable practices. [Company Name] recognizes this need and has taken steps to ensure the 3 Axis CNC Vertical Milling Machine aligns with sustainable manufacturing principles. The machinery incorporates energy-saving features, reducing power consumption and minimizing the carbon footprint. Additionally, the efficient material removal process of this equipment ensures minimal waste generation, contributing to a greener manufacturing ecosystem.Conclusion:[Company Name]'s introduction of the advanced 3 Axis CNC Vertical Milling Machine marks a significant milestone in precision manufacturing. With its superior efficiency, versatility, and precision, this state-of-the-art machinery caters to the diverse needs of various industries. Equipped with cutting-edge technology, user-friendly interface, and sustainability-focused features, manufacturers can now elevate their production capabilities, optimize processes, and streamline operations to meet the demands of tomorrow's manufacturing landscape.