Highest Quality Horizontal Knee Mill Manufacturer in China

By:Admin

With over [XX] years of experience in the industry, China Horizontal Knee Mill Manufacturer has established itself as a trusted provider of quality machine tools. The company's commitment to innovation and continuous improvement has allowed them to stay ahead of the competition and deliver cutting-edge solutions to their customers.

The new range of horizontal knee mills is the result of extensive research and development, aimed at addressing the evolving needs of the manufacturing industry. These machines are built to deliver exceptional accuracy and repeatability, ensuring that every part produced meets the strictest quality standards. Whether it's milling, drilling, or boring, these machines are equipped to handle a variety of tasks with ease.

One of the key features of the new horizontal knee mills is their robust construction. Built to withstand heavy-duty use, these machines are designed for long-term reliability, making them an ideal investment for any production facility. Additionally, they come equipped with advanced CNC controls, allowing for effortless operation and precise tool positioning. This ensures that operators can achieve consistent results, even with complex machining tasks.

Another standout feature of the new horizontal knee mills is their versatility. With a wide range of spindle speeds and feed rates, these machines can accommodate different materials and machining processes. This flexibility makes them suitable for a variety of industries, including automotive, aerospace, and general engineering.

In addition to their technical capabilities, China Horizontal Knee Mill Manufacturer's machines are also designed with user convenience in mind. The company has prioritized ergonomics and accessibility, ensuring that operators can work comfortably and efficiently. This includes features such as easy-to-use control interfaces and convenient access to the work area for setup and maintenance.

As part of their commitment to customer satisfaction, China Horizontal Knee Mill Manufacturer provides comprehensive support for their products. This includes training for operators, as well as ongoing technical assistance and maintenance services. Customers can rest assured that they will receive all the necessary resources to maximize the performance and lifespan of their machines.

The launch of the new horizontal knee mills represents a significant milestone for China Horizontal Knee Mill Manufacturer. By introducing these advanced machines to the market, the company is positioning itself as a leader in the machine tool industry, capable of meeting the diverse needs of modern manufacturing.

In conclusion, China Horizontal Knee Mill Manufacturer's new range of horizontal knee mills is set to make a big impact on the manufacturing industry. With their unparalleled precision, performance, and versatility, these machines are poised to become essential tools for any production facility. Backed by the company's expertise and commitment to customer satisfaction, they offer a compelling solution for manufacturers looking to stay ahead in today's competitive market.

Company News & Blog

New VMC-855: The Latest Breakthrough in Technology in the News

Innovative CNC Machinery Revolutionizes Manufacturing Processes(Mentioning the brand name, VMC-855, and the company introduction)In the fast-paced world of manufacturing, technology continues to play a vital role in shaping the efficiency and productivity of industrial processes. One company at the forefront of this revolution is {Company Name}, renowned for its cutting-edge CNC machinery. One such revolutionary product is their flagship VMC-855, which has the potential to transform manufacturing operations like never before.The VMC-855, a powerful CNC milling machine, brings a new level of precision and versatility to the manufacturing industry. Designed with state-of-the-art technology and impeccable engineering, it allows for complex machining operations and efficiently produces high-quality components. With its advanced features and robust construction, the VMC-855 is set to become an indispensable tool for manufacturers seeking to enhance their performance and gain a competitive edge.One of the standout features of the VMC-855 is its exceptional accuracy. Equipped with advanced linear guide ways and high-precision ball screws, it ensures that every manufactured part meets the strictest tolerances. This level of precision significantly reduces waste and minimizes rework, leading to substantial cost savings for manufacturers. Moreover, the machine's inherent stability guarantees consistent results, making it ideal for industries that demand uncompromising precision, such as aerospace and medical.Another key aspect of the VMC-855 is its exceptional versatility. With a large work table and an impressive spindle speed range, it can accommodate a wide range of materials and machining operations. From solid metal parts to intricate plastic molds, the VMC-855 tackles various materials with ease. Its ability to handle complex 3D geometries and perform simultaneous multi-axis operations unlocks endless manufacturing possibilities. This versatility enables manufacturers to streamline their processes by consolidating multiple operations into a single setup, further minimizing production time and costs.Moreover, the VMC-855 is equipped with cutting-edge automation capabilities. The advanced control system, coupled with intelligent software, allows for seamless integration with other manufacturing systems, such as robotics and automated tool changers. This automation not only reduces manual labor but also enhances overall efficiency and consistency throughout the manufacturing process. With the VMC-855, manufacturers can achieve higher production rates, shorten lead times, and maintain consistent quality with ease.Additionally, the VMC-855 focuses on ergonomic design and user-friendly interfaces. The machine's intuitive control panel and user interface make it accessible to both seasoned professionals and novices alike. Its ergonomic features prioritize operator comfort, ensuring prolonged usage without fatigue. This emphasis on usability enhances productivity while safeguarding the well-being of the machine operators.As one of the industry leaders, {Company Name} is known for its commitment to continuous improvement. The development of the VMC-855 showcases the company's dedication to innovation and their relentless pursuit of excellence. By staying at the forefront of technological advancements, {Company Name} redefines what is possible in the world of manufacturing, setting new benchmarks for precision, efficiency, and reliability.With the introduction of the VMC-855, {Company Name} revolutionizes the manufacturing industry. This powerful CNC milling machine propels manufacturers into a new era of precision, versatility, and automation. By leveraging its exceptional accuracy, versatility, and automation features, manufacturers can expect to improve production rates, reduce costs, and surpass their customers' expectations. As the demand for high-quality and efficient manufacturing continues to grow, the VMC-855 is poised to become a cornerstone of the industry, reinforcing {Company Name}'s commitment to excellence and its position as an innovator in CNC machinery.

High-Performance CNC Working Center for Precision Machining

CNC Working Center Revolutionizes Manufacturing ProcessesIn today’s highly competitive industrial landscape, efficiency and precision are crucial factors in manufacturing processes. This is why the introduction of the CNC Working Center by {Company Name} has been a game changer for the industry. This innovative technology has redefined manufacturing by offering a combination of cutting-edge features and advanced capabilities to streamline production processes and deliver exceptional results.{Company Name} has been a leading name in the manufacturing industry for over two decades, known for its commitment to innovation and quality. The introduction of the CNC Working Center has further solidified its position as a pioneer in the industry, revolutionizing the way products are manufactured.The CNC Working Center is a state-of-the-art machine that combines the latest advancements in technology to offer unparalleled precision, speed, and flexibility. Equipped with advanced CNC (Computer Numerical Control) capabilities, this working center can perform a wide range of tasks with maximum accuracy and efficiency. From cutting and drilling to shaping and finishing, the CNC Working Center can handle a variety of materials with ease, including wood, plastic, metal, and composites.One of the standout features of the CNC Working Center is its ability to automate complex manufacturing processes, eliminating the need for manual intervention and reducing the risk of errors. This not only enhances the overall efficiency of production but also ensures consistent and high-quality results every time. With its user-friendly interface and intuitive controls, operators can easily program the CNC Working Center to perform specific tasks, making it an ideal solution for custom and small-batch manufacturing.Furthermore, the CNC Working Center offers a level of precision that is unattainable through traditional manufacturing methods. Its advanced cutting and shaping capabilities allow for intricate designs and complex geometries, catering to the growing demand for bespoke and customized products in various industries. Whether it is crafting furniture, fabricating automotive parts, or creating intricate prototypes, the CNC Working Center delivers exceptional precision and accuracy, meeting the exacting standards of modern manufacturing.The versatility of the CNC Working Center is another key factor that sets it apart from conventional manufacturing equipment. It can adapt to a wide range of production requirements and accommodate diverse materials and design specifications. This flexibility gives manufacturers the freedom to explore new possibilities and push the boundaries of traditional manufacturing, opening up a world of opportunities for innovation and creativity.In addition to its technical capabilities, the CNC Working Center is also designed with sustainability in mind. By optimizing material usage and reducing waste, this technology is aligned with the growing emphasis on eco-friendly manufacturing practices. By minimizing the environmental impact of production processes, {Company Name} is not only contributing to a greener future but also providing its customers with a competitive edge in an increasingly environmentally conscious market.The introduction of the CNC Working Center represents a significant milestone for {Company Name} and the manufacturing industry as a whole. By leveraging the power of advanced technology, {Company Name} has set a new standard for precision, efficiency, and flexibility in manufacturing processes. As the demand for customized and high-quality products continues to grow, the CNC Working Center is poised to play a pivotal role in shaping the future of manufacturing, offering a glimpse into the limitless possibilities of modern industrial production.In conclusion, the CNC Working Center by {Company Name} has redefined manufacturing processes by offering a combination of cutting-edge features and advanced capabilities to streamline production processes and deliver exceptional results. With its unparalleled precision, speed, and flexibility, this technology has set a new standard for efficiency and quality in the manufacturing industry, paving the way for a future of innovation and sustainable production practices.

High-Quality Vertical Milling Center Factories in China

China Vertical Milling Center Factories: Leading the Way in Precision MachiningIn the world of precision machining, China has long been a leader in the production of high-quality vertical milling centers. With a focus on innovation, quality, and efficiency, Chinese factories have become synonymous with cutting-edge technology and superior performance.One such factory, located in the heart of China, has been at the forefront of this industry for over a decade. Specializing in the production of vertical milling centers, this factory has gained a reputation for delivering top-of-the-line machinery to meet the needs of a wide range of industries, from aerospace and automotive to medical and consumer electronics.With a commitment to excellence, this factory has consistently pushed the boundaries of what is possible in precision machining. By investing in state-of-the-art technology and employing a team of highly skilled engineers and technicians, the factory has been able to develop and manufacture innovative vertical milling centers that are capable of meeting the most demanding machining requirements.One of the key factors that sets this factory apart from its competitors is its dedication to quality control. Each vertical milling center undergoes rigorous testing and inspection to ensure that it meets the highest standards of precision and reliability. This commitment to quality has earned the factory numerous certifications and accolades, solidifying its reputation as a trusted provider of precision machining solutions.In addition to its focus on quality, the factory is also committed to sustainability and environmental responsibility. By implementing eco-friendly manufacturing processes and utilizing energy-efficient technology, the factory has been able to reduce its carbon footprint while maintaining high levels of productivity and efficiency.Furthermore, the factory’s dedication to customer satisfaction has been a driving force behind its success. With a focus on customization and flexibility, the factory is able to work closely with clients to develop tailored solutions that meet their specific machining needs. This collaborative approach has allowed the factory to build strong and lasting relationships with customers around the world, earning their trust and loyalty.Looking to the future, this factory remains committed to innovation and continuous improvement. By staying ahead of the curve and embracing the latest advancements in technology and manufacturing processes, the factory is poised to remain a leader in the global precision machining industry for years to come.In conclusion, China’s vertical milling center factories are setting the standard for precision machining, and this particular factory is a shining example of excellence in this field. With a focus on innovation, quality, and customer satisfaction, this factory has become a trusted provider of high-quality vertical milling centers that are synonymous with precision and reliability. As the demand for precision machining continues to grow, this factory is well-positioned to meet and exceed the needs of industries around the world, solidifying its status as a leader in the global market.

High Precision Machining Centre for CNC: Latest Developments and Applications

Machining Centre In Cnc Brings Advanced Manufacturing Capabilities to the IndustryIn today's digital era, the manufacturing industry is constantly evolving, with advancements in technology driving significant improvements in efficiency and precision. One such advancement is the integration of CNC machining centres, which have revolutionized the way components and parts are manufactured.The integration of a Machining Centre In Cnc has been a game-changer for many companies across various industries, offering unmatched capabilities in terms of speed, accuracy, and flexibility. This cutting-edge technology has significantly enhanced manufacturing processes, enabling companies to produce high-quality parts and components with remarkable precision and efficiency.The versatility of Machining Centre In Cnc has opened up new opportunities for companies to explore complex geometries and designs that were previously difficult, if not impossible, to achieve. By leveraging advanced software and automation, CNC machining centres are capable of producing intricate and intricate parts with unparalleled accuracy, consistency, and repeatability.One company at the forefront of this technological revolution is {}. {} has consistently kept pace with the latest advancements in CNC machining technology, and the integration of Machining Centre In Cnc is a testament to their commitment to delivering top-notch manufacturing capabilities.With the introduction of Machining Centre In Cnc, {} has taken its manufacturing capabilities to new heights. The advanced CNC machining centre has expanded their capacity to produce a wider range of precision components and parts, catering to the diverse needs of their clients across various industries.The Machining Centre In Cnc offers a multitude of benefits, including enhanced productivity, reduced lead times, improved quality control, and cost savings. By leveraging the latest CNC technology, {} has bolstered their position as a leading provider of high-precision components, catering to the demands of industries such as aerospace, automotive, medical, and more.The integration of Machining Centre In Cnc has also allowed {} to optimize their production processes and streamline their operations. By leveraging the advanced capabilities of the CNC machining centre, the company has been able to reduce manual intervention and minimize human error, resulting in improved efficiency and consistency in the manufacturing process.Furthermore, the Machining Centre In Cnc has empowered {} to take on more complex and challenging projects, pushing the boundaries of what is achievable in precision manufacturing. The company's ability to deliver intricate and high-precision components has earned them a reputation for excellence, setting them apart from their competitors in the industry.In addition to bolstering their manufacturing capabilities, {} has also invested in training and development to ensure their team is equipped with the knowledge and skills to fully leverage the capabilities of the Machining Centre In Cnc. This commitment to excellence has allowed {} to stay ahead of the curve and meet the evolving demands of the market.Looking ahead, the integration of Machining Centre In Cnc has positioned {} for continued success and growth in the competitive manufacturing landscape. With a strong focus on innovation and customer satisfaction, the company is poised to leverage the advanced capabilities of CNC machining to drive further advancements in precision manufacturing.In conclusion, the integration of Machining Centre In Cnc has propelled {} to the forefront of precision manufacturing, enabling them to deliver superior quality components and parts to their clients across various industries. With their unwavering commitment to excellence and cutting-edge technology, {} is well-positioned to lead the way in the ever-evolving manufacturing industry.

10 Important Features of a CNC Turning Centre

In the world of manufacturing, the use of advanced technology plays a crucial role in achieving precision and efficiency. One such technology that has revolutionized the manufacturing industry is the turning centre in CNC machining. (Company name) is at the forefront of this technological advancement, providing state-of-the-art turning centres that have redefined the way components and parts are manufactured.With a focus on innovation and excellence, (Company name) has been a leader in the CNC machining industry for over a decade. The company has a strong reputation for delivering high-quality and reliable turning centres that meet the evolving needs of the manufacturing sector. By combining cutting-edge technology with advanced engineering, (Company name) has consistently exceeded the expectations of its customers and set new standards in the industry.The turning centre in CNC machining is a versatile and powerful tool that enables the manufacturing of complex and intricate components with utmost precision. This technology allows for the turning of parts and components with a high degree of accuracy, making it an indispensable asset for industries such as aerospace, automotive, medical, and more. (Company name) has recognized the potential of this technology early on and has made significant investments in research and development to enhance its turning centres and make them more efficient and productive.One of the key features that set (Company name)’s turning centres apart is their advanced control systems. These systems are designed to optimize the performance of the machines, resulting in faster production times and higher accuracy. Additionally, (Company name)’s turning centres are equipped with cutting-edge tools and accessories that further enhance their capabilities, making them ideal for a wide range of machining applications.Furthermore, (Company name) takes pride in its commitment to customer satisfaction. The company offers comprehensive support and training to its customers, ensuring that they are able to maximize the potential of its turning centres. This dedication to customer service has earned (Company name) a solid reputation as a trusted and reliable partner for manufacturers seeking to improve their production capabilities.In addition to its cutting-edge turning centres, (Company name) has also established a strong network of distributors and service centers around the world, providing global access to its innovative products and expert support. This extensive network allows (Company name) to effectively cater to the needs of manufacturers worldwide, reinforcing its position as a market leader in the CNC machining industry.As the manufacturing landscape continues to evolve, the demand for advanced turning centres in CNC machining is expected to rise. (Company name) is well-positioned to meet this demand, thanks to its continuous investment in research and development and its unwavering commitment to excellence. With a diverse portfolio of turning centres that cater to various machining requirements, (Company name) is poised to set new benchmarks in precision and efficiency, further solidifying its standing as a pioneer in the industry.In conclusion, (Company name)’s turning centres in CNC machining have redefined the manufacturing process, enabling companies to achieve unprecedented levels of precision and productivity. With its dedication to innovation, quality, and customer satisfaction, (Company name) is set to continue leading the way in the CNC machining industry, providing manufacturers with the tools they need to stay ahead in a rapidly evolving market.

Highly Efficient Double Pallet Horizontal Machining Center for Increased Productivity

Double Pallet Horizontal Machining Center Revolutionizing Production EfficiencyIn today's fast-paced manufacturing environment, companies are constantly seeking innovative solutions to increase productivity and efficiency. With the demands for high-quality products and tight production schedules, the need for advanced machining centers has become more crucial than ever. Addressing this need, (company name) has introduced a game-changing solution with the latest addition to their machining center lineup - the double pallet horizontal machining center.The double pallet horizontal machining center is designed to revolutionize production efficiency by offering simultaneous machining on two pallets. This innovative design allows for continuous operation, reducing downtime for workpiece loading and unloading. With the ability to switch between pallets seamlessly, the machining center can significantly increase production capacity and reduce lead times. This advanced technology is particularly advantageous for high-volume production runs, where every minute of uptime counts.As a leading manufacturer of cutting-edge CNC machining solutions, (company name) has built a reputation for delivering reliable and high-performance equipment to a wide range of industries. With a focus on continuous innovation and customer-centric solutions, the company has consistently pushed the boundaries of machining technology. The double pallet horizontal machining center is a testament to their commitment to providing cutting-edge solutions that meet the evolving needs of modern manufacturing.With a large work envelope and high spindle speeds, the double pallet horizontal machining center is capable of handling a wide variety of workpieces with precision and efficiency. The machine's robust construction and advanced control systems ensure stable and accurate machining, even in high-speed applications. This level of performance and versatility makes it an ideal choice for industries such as aerospace, automotive, and medical device manufacturing, where complex and tightly toleranced parts are the norm.In addition to its exceptional performance, the double pallet horizontal machining center is also designed with operator convenience and safety in mind. The machine features a user-friendly interface that allows for easy setup and operation, while safety measures such as automatic tool changers and machine guarding systems ensure a secure working environment. These features not only enhance productivity but also contribute to the overall well-being of the workforce.Moreover, the double pallet horizontal machining center is equipped with state-of-the-art monitoring and automation capabilities, enabling seamless integration with modern manufacturing systems. This allows for real-time monitoring of production processes and facilitates the implementation of lights-out machining, further maximizing the machine's productivity. As the industry continues to embrace the principles of Industry 4.0, (company name) remains at the forefront, delivering smart manufacturing solutions that empower businesses to stay competitive in the global market.In conclusion, the introduction of the double pallet horizontal machining center by (company name) marks a significant milestone in the world of manufacturing technology. With its ability to revolutionize production efficiency and versatility, the machine is poised to become a game-changer for businesses striving to meet the demands of modern manufacturing. As the industry looks towards advanced machining solutions to drive innovation and growth, (company name) continues to lead the way with cutting-edge technology that sets new standards for performance, reliability, and productivity.

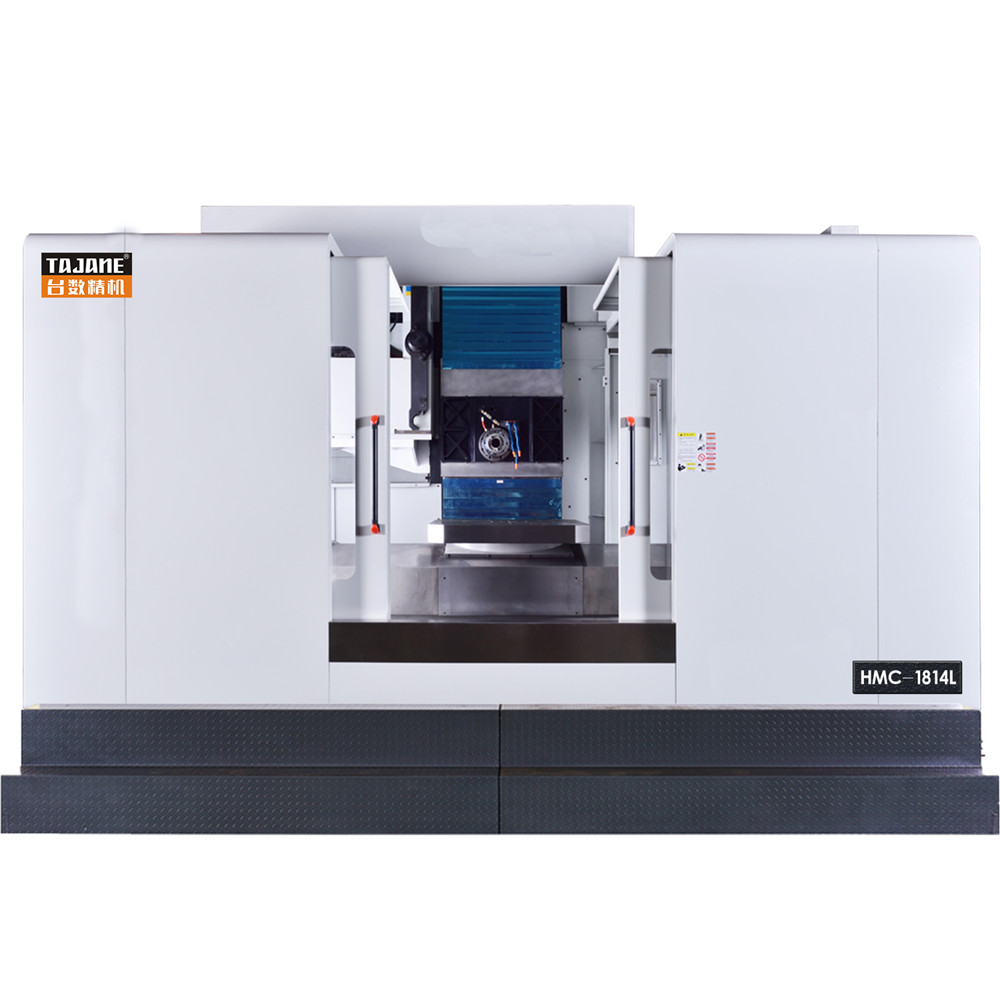

High-Quality Horizontal Machining Center Factory in China for Precision Manufacturing

China Horizontal Machining Center Factory, located in the heart of China's manufacturing hub, is renowned for its high-quality and precision engineering solutions. With a team of experienced engineers and state-of-the-art technology, the factory has established itself as a leading provider of horizontal machining centers in the global market.Established in [year], the factory has consistently strived to innovate and improve its manufacturing processes, resulting in a range of reliable and efficient machining centers that meet the diverse needs of its customers. The factory's commitment to quality and customer satisfaction has earned it a sterling reputation in the industry.One of the key factors that sets China Horizontal Machining Center Factory apart from its competitors is its unwavering dedication to research and development. The factory continually invests in cutting-edge technology and equipment to ensure that its machining centers are at the forefront of industry standards. This commitment to innovation has allowed the factory to stay ahead of the curve and consistently deliver products that exceed customer expectations.In addition to its focus on technological advancements, the factory also places a strong emphasis on quality control throughout the manufacturing process. From the selection of raw materials to the final assembly of the machining centers, every step is meticulously monitored to ensure that each product meets the highest standards of quality and performance. This rigorous quality control process has earned the factory numerous certifications and accolades, further cementing its reputation as a reliable and trustworthy manufacturer.Furthermore, China Horizontal Machining Center Factory is dedicated to providing exceptional customer service and support. The factory works closely with its clients to understand their specific needs and requirements, offering tailored solutions that address their unique challenges. Whether it's providing technical expertise, assisting with installation, or offering after-sales support, the factory goes above and beyond to ensure that its customers are fully satisfied with their machining centers.With a strong foothold in the domestic market, China Horizontal Machining Center Factory has also made significant inroads into the global market. Its products have been widely adopted in various industries, including aerospace, automotive, and medical manufacturing, among others. The factory's ability to adapt to the changing demands of the global market while maintaining its commitment to quality has been a key driver of its success on the international stage.Looking ahead, China Horizontal Machining Center Factory remains dedicated to pushing the boundaries of innovation and excellence in machining center manufacturing. The factory is committed to staying ahead of industry trends, embracing new technologies, and expanding its global footprint. With a steadfast focus on quality, precision, and customer satisfaction, the factory is poised to continue its trajectory of success and solidify its position as a leading provider of horizontal machining centers worldwide.In conclusion, China Horizontal Machining Center Factory stands as a beacon of excellence in the manufacturing industry, delivering top-notch products and services that set the benchmark for quality and innovation. With its unwavering commitment to customer satisfaction, relentless pursuit of technological advancement, and strong global presence, the factory is well-positioned to shape the future of machining center manufacturing for years to come.

Find High-Quality Large Vertical Machining Centers from a Trusted Supplier

Founded in 2005, {Company} is a leading supplier of large vertical machining centers in the manufacturing industry. With a strong focus on innovation and quality, the company has established itself as a trusted partner for businesses looking for high-performance machining solutions.The company’s expertise lies in the design, development, and manufacture of large vertical machining centers that cater to a wide range of industries, including aerospace, automotive, energy, and general machining. These machining centers are known for their precision, reliability, and efficiency, making them a popular choice for businesses looking to optimize their production processes.{Company} takes pride in its commitment to delivering cutting-edge machining solutions that meet the specific needs of its customers. The company’s team of experienced engineers and technicians work closely with clients to understand their requirements and provide customized solutions that address their unique challenges. This customer-centric approach has earned {Company} a solid reputation for delivering high-quality machining centers that consistently exceed expectations.In addition to its focus on innovation and customer satisfaction, {Company} places a strong emphasis on the quality of its products. The company’s state-of-the-art manufacturing facilities are equipped with advanced technology and precision tools, allowing for the production of machining centers that meet the highest industry standards. Furthermore, {Company} has implemented rigorous quality control processes to ensure that every product that leaves its facility is of the utmost quality.{Company} is also dedicated to staying at the forefront of technological advancements in the manufacturing industry. The company invests heavily in research and development to continuously improve its machining solutions and incorporate the latest technology into its products. This commitment to innovation has allowed {Company} to stay ahead of the competition and provide its customers with the most advanced machining solutions available on the market.One of {Company}’s flagship products is its series of large vertical machining centers, which are designed to handle the most demanding machining tasks with exceptional precision and efficiency. These machining centers are engineered to meet the growing needs of the manufacturing industry, offering a combination of robust construction, high-speed performance, and advanced control systems. This makes them an ideal choice for businesses looking to enhance their manufacturing capabilities and achieve higher levels of productivity.In addition to its cutting-edge products, {Company} has built a strong global presence, serving customers in various countries around the world. The company has a robust distribution network and a team of dedicated professionals who provide exceptional support and service to clients worldwide. This has allowed {Company} to build long-lasting relationships with its customers and establish itself as a reliable partner for businesses looking to invest in high-performance machining solutions.Looking ahead, {Company} is committed to continuing its legacy of excellence in the manufacturing industry. The company remains focused on developing innovative products, expanding its global presence, and providing exceptional value to its customers. With its strong track record and unwavering dedication to quality and customer satisfaction, {Company} is well-positioned to remain a leading supplier of large vertical machining centers for years to come.

Top Keyway Milling Factories in China: Boosting Precision Manufacturing

China Keyway Milling Factories are an important part of the manufacturing industry in China. These factories are responsible for producing a wide range of products, from small parts to large components, and play a crucial role in the country’s economy.The keyway milling process is an essential part of the manufacturing process for many industries, including automotive, aerospace, and machinery. It involves cutting keyways, which are small, precise grooves, into metal parts to allow for the insertion of keys or other connecting elements. This process is used to create a secure and precise connection between mating parts, and is essential for ensuring the proper functioning of many mechanical systems.The Keyway Milling Factories in China are known for their high-quality products and advanced manufacturing techniques. These factories utilize the latest technology and equipment to produce keyway-milled parts that meet the highest industry standards. With a focus on precision and accuracy, these factories are able to produce keyway-milled parts that are used in a wide range of applications, from small consumer products to large industrial machinery.One of the leading Keyway Milling Factories in China is {}, which has established itself as a trusted provider of keyway-milled products. With a strong focus on quality and customer satisfaction, the company has become a preferred supplier for many domestic and international clients. {} employs a team of skilled engineers and technicians who are dedicated to producing keyway-milled parts with the highest level of precision and accuracy.In addition to producing high-quality products, {} is committed to innovation and continuous improvement. The company invests heavily in research and development to stay at the forefront of keyway milling technology, and is constantly looking for new ways to improve its manufacturing processes. This dedication to innovation has allowed {} to stay competitive in the market and maintain its position as a leading provider of keyway-milled products.{}’s commitment to quality and innovation has earned the company a reputation for excellence in the industry. With a focus on meeting the needs of its customers, {} has built strong relationships with clients in a variety of industries. The company’s ability to deliver custom solutions and high-quality products has helped it establish a loyal customer base, both in China and abroad.The keyway milling industry in China is a critical part of the country’s manufacturing sector, and companies like {} play a vital role in driving its success. With their focus on quality, innovation, and customer satisfaction, these factories are able to produce keyway-milled products that meet the demanding requirements of modern industries. As China’s manufacturing sector continues to grow and evolve, keyway milling factories will remain a key player in the country’s economy.

An Overview of High Precision Machining Center: Benefits and Uses

The High Precision Machining Center has revolutionized the manufacturing industry with its advanced technology and top-notch precision engineering capabilities. This cutting-edge equipment has become an essential tool for companies looking to achieve the highest levels of accuracy and quality in their production processes.With the ability to perform a wide range of machining operations with incredible precision, the High Precision Machining Center has earned a reputation as one of the most advanced and versatile pieces of equipment in the industry. Its remarkable accuracy and efficiency have made it a valuable asset for a diverse range of industries, including aerospace, automotive, electronics, and medical device manufacturing.The High Precision Machining Center is equipped with state-of-the-art technology that allows for ultra-precise cutting, milling, drilling, and turning operations. Its advanced control systems and high-speed spindles ensure that every machined part meets the strictest tolerance requirements, resulting in superior quality and consistency.One of the key features of the High Precision Machining Center is its ability to handle complex and intricate geometries with ease. This level of precision and versatility allows manufacturers to produce a wide variety of components and parts with the utmost accuracy, regardless of their complexity or intricacy.In addition to its incredible precision, the High Precision Machining Center also offers unmatched efficiency and productivity. Its high-speed machining capabilities enable manufacturers to significantly reduce cycle times and increase throughput, leading to greater overall output and improved operational efficiency.Furthermore, the High Precision Machining Center is designed for seamless integration with advanced automation systems, further enhancing its capabilities and allowing for continuous, unmanned operation. This level of automation not only improves production efficiency but also reduces the potential for errors and inconsistencies, ultimately leading to higher-quality finished products.The company behind the High Precision Machining Center, {} has been a leading provider of advanced manufacturing solutions for over [X] years. With a strong focus on innovation and continuous improvement, {} has established itself as a trusted partner for companies looking to stay at the forefront of technological advancements in the industry.{}'s commitment to quality and excellence is evident in the design and performance of the High Precision Machining Center. The company's engineering expertise and rigorous quality control processes ensure that every machine meets the highest standards of performance and reliability, providing manufacturers with the confidence and peace of mind they need to meet their most demanding production requirements.In addition to its superior products, {} is also known for its exceptional customer service and support. The company's team of skilled engineers and technicians are dedicated to helping customers maximize the performance and value of their equipment, providing comprehensive training, technical assistance, and ongoing maintenance services to ensure that every High Precision Machining Center operates at its best for years to come.As the manufacturing industry continues to evolve and demand for high-quality, precision-engineered parts grows, the High Precision Machining Center from {} is poised to play a crucial role in helping companies meet these evolving challenges. With its unmatched precision, efficiency, and reliability, this advanced machining equipment is shaping the future of manufacturing, empowering companies to achieve new levels of success and competitiveness in the global marketplace.In conclusion, the High Precision Machining Center from {} has set a new standard for precision machining and manufacturing excellence. Its advanced technology, exceptional performance, and robust support from {} make it the ideal solution for companies seeking to achieve the highest levels of quality and productivity in their production processes. With its proven track record and ongoing commitment to innovation, {} is poised to remain a leader in the industry, providing cutting-edge solutions that empower manufacturers to thrive in an ever-changing and demanding marketplace.