Ultimate Guide to Horizontal Knee Mills: Everything You Need to Know

By:Admin

The Horizontal Knee Mill offered by {company} is a highly versatile and reliable machine that is designed to meet the needs of modern machining operations. With its robust construction and advanced features, this machine is capable of handling a wide range of milling tasks with ease and efficiency. Whether it is producing complex components or simple parts, this Horizontal Knee Mill is an ideal choice for a variety of machining requirements.

The {company} is a leading manufacturer of industrial machinery and equipment, with a strong reputation for quality and innovation. With a focus on delivering cutting-edge solutions for the manufacturing industry, the company has established itself as a trusted provider of a wide range of machinery and equipment. Its commitment to excellence and customer satisfaction has made it a preferred choice for businesses looking for high-quality, reliable machines that can meet their specific needs.

The Horizontal Knee Mill offered by {company} is a testament to the company's dedication to delivering top-notch products that can enhance the capabilities of manufacturing operations. Equipped with state-of-the-art technology and precision engineering, this machine is designed to deliver high accuracy and performance, making it an essential tool for any machining workshop. Its robust construction and user-friendly design make it a valuable addition to any manufacturing facility, providing the capabilities needed to produce high-quality components and products.

One of the key features of the Horizontal Knee Mill offered by {company} is its versatility and flexibility. With its ability to handle a wide range of materials and cutting tasks, this machine is well-suited for a variety of machining applications. Whether it is milling, drilling, or boring, this machine is capable of delivering precise and consistent results, making it a valuable asset for businesses looking to enhance their manufacturing capabilities. Its intuitive controls and advanced features also make it easy to operate, ensuring that users can achieve the desired results with minimal effort.

In addition to its performance and versatility, the Horizontal Knee Mill offered by {company} is also designed with user safety and convenience in mind. With its comprehensive safety features and ergonomic design, this machine is engineered to ensure a safe and comfortable working environment for operators. This not only helps to enhance productivity and efficiency but also reflects the company's commitment to ensuring the well-being of its customers.

The Horizontal Knee Mill offered by {company} is a clear example of the company's dedication to delivering top-of-the-line machinery and equipment for the manufacturing industry. With its exceptional performance, versatility, and safety features, this machine is a valuable asset for businesses looking to enhance their machining capabilities. As the industry continues to evolve, {company} remains committed to delivering innovative solutions that can meet the ever-changing needs of modern manufacturing operations.

In conclusion, the Horizontal Knee Mill offered by {company} is a superior machine that is designed to meet the stringent requirements of modern machining operations. With its exceptional performance, versatility, and safety features, this machine is an invaluable asset for businesses seeking to enhance their manufacturing capabilities. As a leading manufacturer of industrial machinery and equipment, {company} continues to set the standard for quality and innovation, providing businesses with the tools they need to succeed in today's competitive market.

Company News & Blog

Top Benchtop CNC Machine Options for Precision Cutting and Engraving

In today's rapidly advancing technology industry, the demand for precision manufacturing tools is at an all-time high. From small businesses to large industrial corporations, the need for efficient and accurate machinery is crucial for producing high-quality products. That's where the Benchtop CNC Machine comes into play. This advanced piece of equipment is revolutionizing the way manufacturers operate, providing a reliable and cost-effective solution for a wide range of machining needs.The Benchtop CNC Machine, offered by {}, is a powerful and versatile tool that is designed to meet the demands of modern manufacturing. This compact yet robust machine is capable of performing a variety of tasks, including milling, drilling, and cutting, with a level of precision that is unmatched by traditional machining methods. With its user-friendly interface and advanced control system, this CNC machine is perfect for both experienced machinists and those who are new to the world of CNC machining.One of the key features of the Benchtop CNC Machine is its compact size, which makes it well-suited for small workshops or production facilities with limited space. Despite its small footprint, this machine delivers exceptional performance and can handle a wide range of materials, from plastic and wood to aluminum and steel. This versatility makes it an ideal choice for businesses looking to expand their capabilities without investing in large, expensive equipment.In addition to its impressive performance, the Benchtop CNC Machine is also known for its reliability and durability. Constructed from high-quality materials and precision-engineered components, this machine is built to withstand the rigors of continuous use in a production environment. This means that businesses can rely on this CNC machine to deliver consistent and accurate results, day in and day out.Furthermore, the Benchtop CNC Machine is backed by a team of knowledgeable and experienced professionals who are dedicated to providing exceptional customer support. Whether it's technical assistance, training, or troubleshooting, customers can count on the team at {} to provide the support they need to keep their machines running smoothly. This level of support is crucial for businesses that rely on their machining equipment to meet tight production deadlines and maintain high standards of quality.In conclusion, the Benchtop CNC Machine offered by {} is a game-changer for manufacturers looking to boost their efficiency and precision. With its compact size, powerful performance, and reliable support, this CNC machine is a valuable asset for any business looking to stay ahead in today's competitive market. Whether it's used for prototyping, production, or custom fabrication, the Benchtop CNC Machine delivers the results that businesses need to succeed. With its advanced technology and user-friendly design, this machine is sure to make a significant impact on the world of manufacturing for years to come.

High-quality Large Vertical Machining Center Factory in China

China Large Vertical Machining Center Factory (LMCF) is a leading manufacturer of high-quality vertical machining centers in China. The company specializes in producing a wide range of vertical machining centers that are used in various industries such as automotive, aerospace, and defense.Established in 2003, LMCF has become a trusted name in the manufacturing industry for its commitment to quality, precision, and innovation. The company has a state-of-the-art manufacturing facility that is equipped with the latest technology and machinery to ensure the production of top-notch vertical machining centers.One of the key factors that sets LMCF apart from its competitors is its focus on research and development. The company has a team of highly skilled engineers and technicians who are constantly working on developing new and improved machining centers to meet the ever-changing needs of the industry. This relentless pursuit of innovation has led to LMCF's reputation as a pioneer in the field of vertical machining centers.In addition to its cutting-edge technology, LMCF also places a strong emphasis on quality control. The company has a rigorous quality assurance process in place to ensure that each machining center that leaves its facility meets the highest standards of quality and performance. This commitment to excellence has earned LMCF the trust and loyalty of customers both domestically and internationally.Furthermore, LMCF is dedicated to providing exceptional customer service. The company has a team of experienced professionals who are readily available to provide technical support, training, and maintenance services to its customers. This commitment to customer satisfaction has contributed to LMCF's success in building long-lasting relationships with its clients.One of the flagship products of LMCF is its large vertical machining centers. These machines are designed to handle heavy-duty machining tasks with precision and efficiency. They are equipped with advanced features such as high-speed spindles, multiple-axis controls, and automated tool changers, making them ideal for a wide range of applications.The large vertical machining centers manufactured by LMCF are known for their reliability and durability. These machines are built to withstand the most demanding manufacturing environments, making them a popular choice among industrial manufacturers who require high-performance machining solutions.In recent news, LMCF has announced the launch of its latest large vertical machining center model, the VMC-L900. This new model boasts enhanced capabilities and improved performance, making it an ideal choice for manufacturers looking to boost their productivity and efficiency.The VMC-L900 is equipped with a powerful spindle and high-speed machining capabilities, allowing for faster and more precise cutting. Additionally, it features a large work envelope and a robust construction, making it suitable for machining large and complex parts.Furthermore, the VMC-L900 comes with advanced control systems and software that are designed to streamline the machining process and optimize productivity. Its user-friendly interface and intuitive functions make it easy for operators to set up and operate the machine, reducing setup time and increasing overall efficiency.LMCF is confident that the VMC-L900 will be well-received in the market, as it addresses the growing demand for high-performance machining solutions in various industries. The company expects that the new model will further solidify its position as a leading manufacturer of large vertical machining centers in China and beyond.As LMCF continues to innovate and expand its product line, it remains committed to its core values of quality, precision, and customer satisfaction. The company's dedication to excellence and its relentless pursuit of technological advancement have positioned it as a key player in the global manufacturing industry. With its latest offering, the VMC-L900, LMCF is set to raise the bar for large vertical machining centers and meet the evolving needs of the industry.

China Vertical Machining Center Factories: Discover the Best VMC Manufacturers

China's Vertical Machining Center (VMC) Factories: Pioneering Precision and InnovationVertical Machining Centers (VMCs) have emerged as a vital component of the global manufacturing industry, offering a diverse range of capabilities. China, known for its manufacturing prowess, is home to several prominent VMC factories that are revolutionizing the sector with their cutting-edge technology, precision, and commitment to innovation.One such leading VMC factory in China is dedicated to the production of high-quality, state-of-the-art VMCs. With a focus on meeting the demands of a rapidly evolving industry, this factory has established itself as a key player in the global market.The factory's cutting-edge production facility is equipped with the latest machinery and advanced manufacturing processes. With a highly skilled workforce and a stringent quality control system, the factory ensures that its VMCs adhere to the highest standards of precision and reliability. The integration of advanced technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM) enables the factory to produce VMCs that are at the forefront of technological advancements.The factory's commitment to innovation is evident in its extensive research and development (R&D) activities. With a dedicated team of engineers and designers, the factory continuously explores new avenues and ideas to enhance the performance and capabilities of their VMCs. By keeping abreast of the latest technological trends and advancements, the factory ensures that its VMCs are equipped with state-of-the-art features and functionalities, thereby maximizing their productivity and usability.Furthermore, the factory recognizes the importance of customization in meeting the diverse needs of its customers. With a focus on providing tailored solutions, the factory offers a wide range of options and configurations for its VMCs. From different spindle speeds and tool changers to various worktable sizes and cutting capacities, customers can choose a VMC that perfectly aligns with their specific requirements. This commitment to customization sets the factory apart from its competitors and has contributed to its success in the global market.The factory's dedication to customer satisfaction is exemplified by its comprehensive after-sales service. With a well-established network of support centers and a team of skilled service engineers, the factory ensures prompt and efficient response to customer queries and technical issues. This commitment to customer support has earned the factory a reputation for providing exceptional service, further strengthening its position in the industry.In addition to its focus on manufacturing excellence, the factory is also environmentally conscious. It adopts sustainable practices throughout its production processes, adhering to strict environmental regulations and striving for energy efficiency. By implementing eco-friendly measures, the factory minimizes its carbon footprint and contributes to a greener future.Looking ahead, the factory aims to further expand its global presence by tapping into emerging markets and forging strategic partnerships. By leveraging its expertise and reputation as a leading VMC manufacturer, the factory is well-positioned to capitalize on the growing demand for precision machining solutions worldwide.In conclusion, China's VMC factories are leading the way in the global manufacturing industry, driven by their commitment to precision, technological innovation, and customer satisfaction. With cutting-edge technology, a focus on customization, and a dedication to sustainability, these factories are poised to shape the future of VMC manufacturing and propel the industry to new heights.

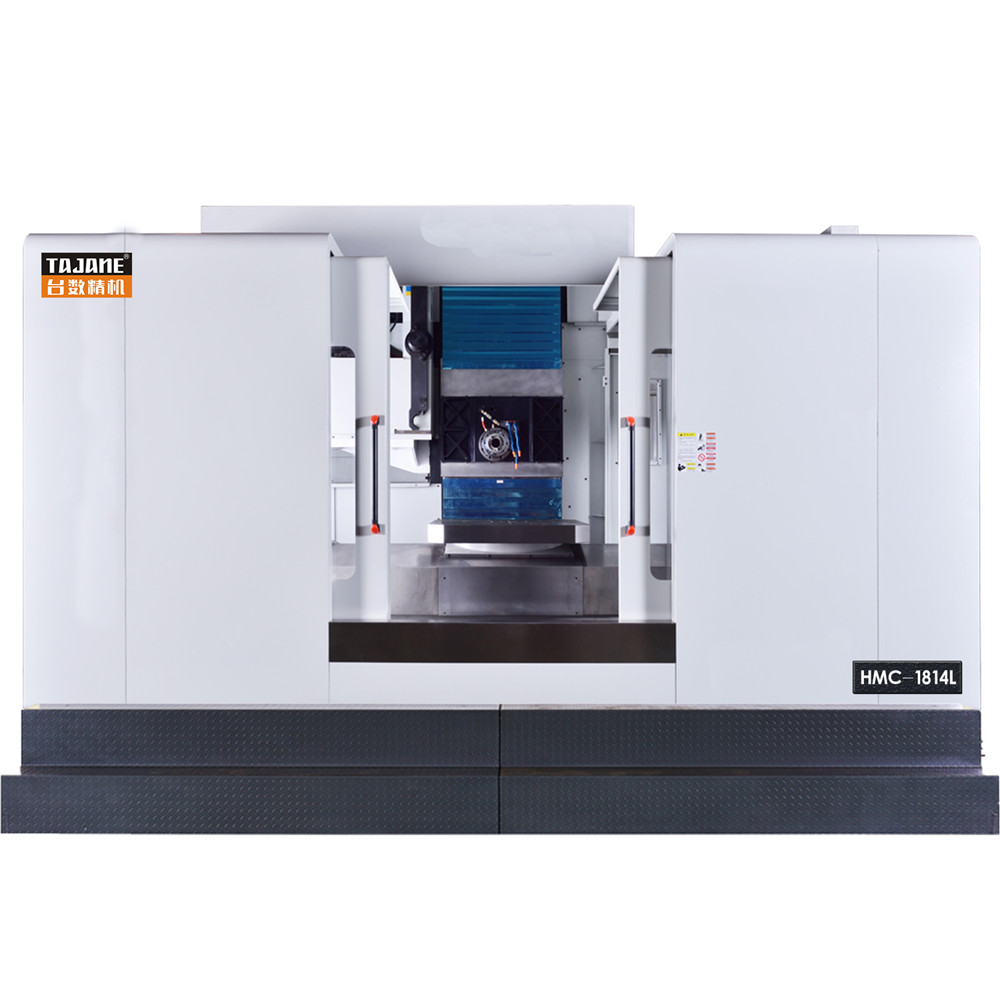

Top Supplier of Double Pallet Horizontal Machining Centers Available

Double Pallet Horizontal Machining Center Supplier takes pride in the quality and precision of their products. With over 20 years of experience in the industry, they have established themselves as a leading supplier of machining centers for various industries such as aerospace, automotive, and medical devices. Their dedication to innovation and customer satisfaction has allowed them to develop cutting-edge solutions that meet the demands of modern manufacturing.One of the standout products in their portfolio is the Double Pallet Horizontal Machining Center. This state-of-the-art machine is designed for high-speed and high-precision machining, making it an ideal choice for manufacturers looking to boost their productivity and efficiency. The double pallet design allows for continuous operation by switching between pallets during machining, minimizing downtime and maximizing output. This feature is particularly valuable for companies that require continuous production with minimal interruptions.In addition to its impressive performance capabilities, the Double Pallet Horizontal Machining Center also boasts a spacious work envelope, allowing for the machining of large and complex parts with ease. This versatility makes it a valuable asset for manufacturers with a wide range of production needs. Furthermore, the machine is equipped with advanced controls and software that streamline programming and ensure consistent and accurate results.As a reliable supplier, Double Pallet Horizontal Machining Center Supplier understands the importance of after-sales service and support. They offer comprehensive training for machine operators and maintenance personnel to ensure optimal performance and longevity of their products. Additionally, their team of skilled technicians is readily available to provide assistance and technical expertise whenever needed. This commitment to customer care sets them apart as a trusted partner for manufacturers seeking long-term solutions and reliability.With a strong focus on research and development, Double Pallet Horizontal Machining Center Supplier continuously seeks to enhance their products and stay ahead of industry trends. Their dedication to innovation has led to the introduction of several patented technologies that improve machining processes and deliver superior results. By staying at the forefront of technological advancements, they aim to empower their customers with the tools they need to thrive in an increasingly competitive market.The company's success is built on a foundation of integrity, professionalism, and a deep understanding of their customers' needs. They strive to establish lasting relationships with their clients based on mutual trust and collaboration. By working closely with manufacturers to identify their specific requirements and challenges, Double Pallet Horizontal Machining Center Supplier is able to tailor their solutions to deliver maximum value and impact.In conclusion, Double Pallet Horizontal Machining Center Supplier stands out as a reliable and innovative partner for manufacturers seeking high-quality machining solutions. With a focus on precision, performance, and customer satisfaction, they have earned a strong reputation in the industry. Their Double Pallet Horizontal Machining Center is a testament to their commitment to excellence and their ability to meet the evolving needs of modern manufacturing. As they continue to push the boundaries of technological innovation, they are poised to make a significant impact on the industry and the businesses they serve.

New VMC-855: The Latest Breakthrough in Technology in the News

Innovative CNC Machinery Revolutionizes Manufacturing Processes(Mentioning the brand name, VMC-855, and the company introduction)In the fast-paced world of manufacturing, technology continues to play a vital role in shaping the efficiency and productivity of industrial processes. One company at the forefront of this revolution is {Company Name}, renowned for its cutting-edge CNC machinery. One such revolutionary product is their flagship VMC-855, which has the potential to transform manufacturing operations like never before.The VMC-855, a powerful CNC milling machine, brings a new level of precision and versatility to the manufacturing industry. Designed with state-of-the-art technology and impeccable engineering, it allows for complex machining operations and efficiently produces high-quality components. With its advanced features and robust construction, the VMC-855 is set to become an indispensable tool for manufacturers seeking to enhance their performance and gain a competitive edge.One of the standout features of the VMC-855 is its exceptional accuracy. Equipped with advanced linear guide ways and high-precision ball screws, it ensures that every manufactured part meets the strictest tolerances. This level of precision significantly reduces waste and minimizes rework, leading to substantial cost savings for manufacturers. Moreover, the machine's inherent stability guarantees consistent results, making it ideal for industries that demand uncompromising precision, such as aerospace and medical.Another key aspect of the VMC-855 is its exceptional versatility. With a large work table and an impressive spindle speed range, it can accommodate a wide range of materials and machining operations. From solid metal parts to intricate plastic molds, the VMC-855 tackles various materials with ease. Its ability to handle complex 3D geometries and perform simultaneous multi-axis operations unlocks endless manufacturing possibilities. This versatility enables manufacturers to streamline their processes by consolidating multiple operations into a single setup, further minimizing production time and costs.Moreover, the VMC-855 is equipped with cutting-edge automation capabilities. The advanced control system, coupled with intelligent software, allows for seamless integration with other manufacturing systems, such as robotics and automated tool changers. This automation not only reduces manual labor but also enhances overall efficiency and consistency throughout the manufacturing process. With the VMC-855, manufacturers can achieve higher production rates, shorten lead times, and maintain consistent quality with ease.Additionally, the VMC-855 focuses on ergonomic design and user-friendly interfaces. The machine's intuitive control panel and user interface make it accessible to both seasoned professionals and novices alike. Its ergonomic features prioritize operator comfort, ensuring prolonged usage without fatigue. This emphasis on usability enhances productivity while safeguarding the well-being of the machine operators.As one of the industry leaders, {Company Name} is known for its commitment to continuous improvement. The development of the VMC-855 showcases the company's dedication to innovation and their relentless pursuit of excellence. By staying at the forefront of technological advancements, {Company Name} redefines what is possible in the world of manufacturing, setting new benchmarks for precision, efficiency, and reliability.With the introduction of the VMC-855, {Company Name} revolutionizes the manufacturing industry. This powerful CNC milling machine propels manufacturers into a new era of precision, versatility, and automation. By leveraging its exceptional accuracy, versatility, and automation features, manufacturers can expect to improve production rates, reduce costs, and surpass their customers' expectations. As the demand for high-quality and efficient manufacturing continues to grow, the VMC-855 is poised to become a cornerstone of the industry, reinforcing {Company Name}'s commitment to excellence and its position as an innovator in CNC machinery.

Small Vertical Machining Center Supplier in China: A Complete Guide

China Small Vertical Machining Center Supplier Leads the Industry in Precision EngineeringIn the world of precision engineering, finding the right supplier for small vertical machining centers can be a daunting task. However, in China, one company stands out among the rest. With a commitment to quality, innovation, and customer satisfaction, this small vertical machining center supplier has become a leader in the industry.Founded in 2005, the company has quickly risen to prominence in the manufacturing world. Their state-of-the-art facility is equipped with the latest technology and machinery, allowing them to produce high-quality small vertical machining centers that meet the stringent demands of their customers. Their team of highly skilled engineers and technicians work tirelessly to ensure that every product that leaves their facility is of the highest quality.One of the key factors that set this company apart from its competitors is its commitment to innovation. They are constantly researching and developing new technologies and processes to improve the efficiency and precision of their small vertical machining centers. This dedication to innovation has allowed them to stay ahead of the curve and meet the ever-evolving needs of the industry.In addition to their innovative approach, the company also places a strong emphasis on customer satisfaction. They work closely with their clients to understand their specific needs and requirements, and then tailor their products and services to meet those needs. This customer-centric approach has earned them a reputation for reliability and trustworthiness, making them the go-to supplier for small vertical machining centers in China.Furthermore, the company is committed to sustainability and environmental responsibility. They have implemented strict guidelines and practices to minimize their impact on the environment, and they are constantly exploring new ways to make their operations more eco-friendly. This commitment to sustainability not only benefits the environment, but it also reflects the company's dedication to ethical and responsible business practices.As a result of their commitment to quality, innovation, customer satisfaction, and sustainability, this small vertical machining center supplier has become a leader in the industry. Their products are renowned for their precision, reliability, and durability, making them the top choice for manufacturers around the world.In a recent interview, the company's CEO expressed his pride in the company's accomplishments and outlined their vision for the future. He emphasized the company's commitment to staying at the forefront of the industry by continuing to invest in research and development, embracing new technologies, and expanding their product offerings. He also highlighted their dedication to fostering strong and long-lasting relationships with their customers, as well as their commitment to environmental stewardship.Looking ahead, the company has ambitious plans for growth and expansion. They are looking to expand their reach into new markets and further solidify their position as a global leader in the manufacturing industry. They are also exploring new opportunities for collaboration and partnerships with other industry leaders, with the goal of driving innovation and pushing the boundaries of what is possible in precision engineering.With their unwavering commitment to quality, innovation, customer satisfaction, and sustainability, this small vertical machining center supplier is well-positioned to lead the industry into the future. Their exceptional products, forward-thinking approach, and strong ethical values make them a force to be reckoned with in the world of precision engineering. As they continue to grow and evolve, this company is sure to remain a driving force in the industry for many years to come.

Top Keyway Milling Manufacturer in China Shaping Industry

China Keyway Milling Manufacturer, also known as CKM, is a leading player in the milling industry. With a strong focus on innovation, quality, and customer satisfaction, CKM has established itself as a reliable and trusted provider of keyway milling solutions.Founded in 2008, CKM has grown steadily over the years and has become one of the most sought-after milling manufacturers in China. The company's success can be attributed to its commitment to continuous improvement and cutting-edge technology. CKM continually invests in research and development to stay at the forefront of the industry, ensuring that its customers have access to the latest advancements in milling technology.One of the key factors that sets CKM apart from its competitors is its dedication to quality. The company follows strict quality control measures at every stage of the manufacturing process to ensure that its products meet the highest standards. CKM's team of skilled technicians and engineers conduct thorough testing and inspection to guarantee that each milling machine leaving the factory is of superior quality and performance.CKM offers a wide range of keyway milling machines, catering to various industries and applications. Whether it is for automobile manufacturing, aerospace, or general engineering, CKM has a milling solution that meets the specific needs of its customers. The company's machines are known for their precision, durability, and efficiency, making them the preferred choice for many businesses around the world.In addition to its cutting-edge technology and high-quality products, CKM also places great emphasis on customer satisfaction. The company strives to build long-term relationships with its clients by providing outstanding after-sales service and support. CKM's team of experienced technicians is available to assist customers with any technical issues or queries they may have, ensuring that their milling machines operate at optimal performance.To further enhance customer experience, CKM also offers customization options for its milling machines. The company understands that different industries have unique requirements, and therefore, provides tailor-made solutions to meet those specific needs. CKM's team works closely with customers to understand their individual requirements and design milling machines that are perfectly suited to their applications.In addition to its domestic market, CKM has also been expanding its presence in the global market. The company's commitment to quality and customer satisfaction has helped it gain a strong foothold in various countries around the world. CKM's milling machines are now being used by customers in North America, Europe, Southeast Asia, and many other regions.Looking ahead, CKM has ambitious plans for growth and expansion. The company aims to further strengthen its position in the milling industry by continuing to invest in research and development, expanding its product portfolio, and exploring new markets. CKM's unwavering commitment to innovation and quality ensures that it will remain a top choice for businesses seeking efficient and reliable keyway milling solutions.In conclusion, CKM is a leading keyway milling manufacturer in China, known for its commitment to innovation, quality, and customer satisfaction. With a wide range of high-quality milling machines, customized solutions, and exceptional after-sales support, CKM has established itself as a trusted partner for businesses in various industries worldwide. As CKM continues to grow and expand its global presence, it is set to become an even more prominent player in the milling industry.

High-performance and Robust VMC-855 for Efficient Operations

VMC-855 Advanced Machining Center Takes Manufacturing Efficiency to a New LevelIn today’s fast-paced manufacturing industry, companies are constantly seeking ways to improve efficiency and reduce production time. One company at the forefront of this movement is {}, a leading provider of advanced machining solutions. With a strong focus on innovation and cutting-edge technology, the company has developed the VMC-855, an advanced machining center that promises to take manufacturing efficiency to a whole new level.The VMC-855 is the latest addition to {}’s lineup of high-performance machining centers, and it comes packed with a host of features that set it apart from the competition. With a robust and rigid structure, the VMC-855 is capable of handling a wide range of machining operations with unparalleled precision and efficiency. Its advanced spindle design, combined with high-speed linear guides, ensures smooth and stable operation, even during the most demanding machining tasks.One of the key highlights of the VMC-855 is its advanced control system, which is designed to optimize machining processes and maximize productivity. Equipped with the latest CNC technology, the control system provides users with a user-friendly interface that allows for quick and easy programming, setup, and monitoring of machining operations. This enables operators to make rapid adjustments and fine-tune machining parameters on the fly, leading to significant time savings and improved overall efficiency.In addition to its advanced control system, the VMC-855 also comes with a range of productivity-enhancing features that further contribute to its superior performance. A high-capacity tool changer, for example, enables seamless and rapid tool changes, minimizing downtime and keeping machining operations running smoothly. Furthermore, the machine’s automatic tool length measurement and breakage detection system help to ensure consistent and reliable machining results, even during long production runs.Another standout feature of the VMC-855 is its adaptability to a wide range of machining applications. Whether it’s milling, drilling, tapping, or any other machining operation, the VMC-855 is capable of delivering exceptional results across the board. Its versatile design and comprehensive range of customization options allow it to be tailored to specific manufacturing requirements, making it a versatile and scalable solution for a wide variety of industries.Moreover, the VMC-855 is not only designed for high performance but also for the utmost safety and ergonomics. It incorporates safety features such as fully enclosed guarding, interlocking doors, and emergency stop buttons to ensure operator safety at all times. Additionally, its ergonomic design and accessibility features make it easy for operators to load and unload workpieces, further enhancing overall productivity and workflow efficiency.With its advanced technology, robust construction, and unmatched versatility, the VMC-855 represents a significant leap forward in machining center technology. By combining cutting-edge features with the company’s reputation for quality and reliability, the VMC-855 is poised to set a new standard for manufacturing efficiency and productivity across the industry.“With the introduction of the VMC-855, we are taking a giant leap forward in our mission to provide our customers with the most advanced and efficient machining solutions available,” said a spokesperson for {}. “We believe that the VMC-855 will help our customers achieve new levels of productivity, precision, and profitability in their manufacturing operations, and we are excited to see the impact it will have on the industry as a whole.”In conclusion, the VMC-855 represents a significant breakthrough in machining center technology, offering a winning combination of advanced features, exceptional performance, and unparalleled versatility. With its ability to meet the diverse needs of modern manufacturing operations, the VMC-855 is poised to become a game-changer for businesses looking to maximize efficiency and stay ahead of the competition. As the industry continues to evolve, solutions like the VMC-855 will play a crucial role in driving progress and innovation in manufacturing.

New Study Reveals VMC-1890's Impact on Market Trends

VMC-1890, a cutting-edge machining center, has been making waves in the manufacturing industry with its high precision and efficiency. Developed by a leading machinery manufacturing company, this innovative machine has become a game-changer for companies looking to streamline their production processes and improve overall productivity.The VMC-1890 is equipped with state-of-the-art technology and features a large working area, making it suitable for a wide range of machining applications. Its high-speed spindle and advanced tool changer allow for quick and precise machining, while its sturdy and stable construction ensures consistent and reliable performance.With the ability to handle a variety of materials, including metal, plastic, and composite, the VMC-1890 is a versatile solution for manufacturers across different sectors. Its advanced control system and user-friendly interface make operation and programming straightforward, minimizing downtime and increasing throughput.Furthermore, the VMC-1890 is designed with energy efficiency in mind, reducing power consumption and operating costs for companies. Its environmentally friendly features align with the growing demand for sustainable manufacturing practices, enhancing its appeal to businesses looking to reduce their carbon footprint.In addition to its impressive technical specifications, the VMC-1890 is backed by comprehensive customer support and a team of experienced engineers who provide ongoing maintenance and technical assistance. This ensures that businesses can maximize the performance and lifespan of their investment, contributing to long-term success and growth.Since its launch, the VMC-1890 has garnered positive feedback from businesses that have incorporated it into their production processes. Many have reported significant improvements in productivity, quality, and overall efficiency, leading to cost savings and enhanced competitiveness in the market."We invested in the VMC-1890 to upgrade our machining capabilities, and it has exceeded our expectations in terms of performance and reliability," said a satisfied customer. "It has allowed us to fulfill orders faster and with greater precision, giving us a competitive edge in our industry."The success of the VMC-1890 has not gone unnoticed, with an increasing number of companies showing interest in integrating this cutting-edge machining center into their operations. Its reputation for superior quality and its ability to deliver consistent results have made it a sought-after solution for businesses striving for operational excellence.With the manufacturing industry evolving at a rapid pace, the VMC-1890 has emerged as a leading choice for companies looking to modernize their production capabilities and stay ahead of the competition. Its combination of advanced technology, versatility, and reliability positions it as a valuable asset for businesses seeking to optimize their manufacturing processes and achieve sustainable growth.In conclusion, the VMC-1890, developed by a leading machinery manufacturing company, stands out as a top-tier solution for businesses aiming to enhance their production efficiency and output quality. Its cutting-edge technology, user-friendly operation, and robust construction make it an ideal choice for a wide range of machining applications. As the manufacturing industry continues to evolve, the VMC-1890 has proven to be a game-changer, empowering businesses to achieve their goals and succeed in today's competitive market.

Advanced CNC Horizontal Mills for Precision Machining

CNC Horizontal Mills: Revolutionizing Manufacturing at {}In the world of manufacturing, precision and efficiency are key components to achieving success. As technology continues to advance, so does the equipment used in the manufacturing process. One such piece of technology that has revolutionized the industry is the CNC (Computer Numerical Control) Horizontal Mill. These machines have become an essential tool for manufacturers looking to produce high-quality, intricate parts with speed and accuracy.At {}, we have invested in state-of-the-art CNC Horizontal Mills to ensure that we stay ahead of the curve in the constantly evolving manufacturing landscape. These machines have allowed us to take our production capabilities to the next level, enabling us to deliver exceptional quality products to our customers in a timely manner.Our CNC Horizontal Mills feature a horizontal spindle orientation, which allows for the efficient machining of complex parts from multiple angles. This versatility has opened up a world of possibilities for us, as we are now able to take on a wider range of projects with ease. Whether it's producing intricate components for the aerospace industry or creating precision parts for the automotive sector, our CNC Horizontal Mills have proven to be invaluable assets for our business.In addition to their versatility, these machines are also equipped with advanced control systems that enable us to program and execute complex machining operations with precision. This level of control ensures that we are able to maintain tight tolerances and achieve the exact specifications required for each part we produce. As a result, we have been able to significantly improve our overall product quality, leading to higher customer satisfaction and repeat business.Furthermore, the automation capabilities of our CNC Horizontal Mills have allowed us to streamline our production processes and reduce lead times. With the ability to operate continuously and with minimal human intervention, we are able to maximize the efficiency of our manufacturing operations. This not only benefits us by increasing our productivity, but it also translates to cost savings for our customers, as we are able to offer competitive pricing without sacrificing quality.At {}, we understand the importance of staying ahead of the competition, which is why we have made significant investments in our manufacturing capabilities. Our CNC Horizontal Mills are a testament to our commitment to delivering exceptional quality products and exceeding the expectations of our customers. With these machines at our disposal, we are confident in our ability to take on new challenges and continue to raise the bar for excellence in the manufacturing industry.In conclusion, CNC Horizontal Mills have become an indispensable tool for modern manufacturers, and {} is proud to be at the forefront of this technological advancement. With these machines, we have been able to elevate our production capabilities and deliver superior quality products to our customers. As we look to the future, we are excited about the possibilities that our CNC Horizontal Mills will unlock for our business, and we are committed to leveraging this technology to drive continued success and growth.