Advanced CNC Milling Machine for Versatile Machining Operations

By:Admin

The global manufacturing industry has witnessed remarkable advancements in precision engineering, thanks to the advent of Computer Numerical Control (CNC) machining technology. CNC machining has revolutionized the production processes across various sectors, offering unparalleled accuracy, efficiency, and consistency in the fabrication of complex parts and components. Among the leading manufacturers in the CNC machinery industry, [Company Name] has made significant strides in delivering cutting-edge solutions to meet the evolving demands of the manufacturing sector.

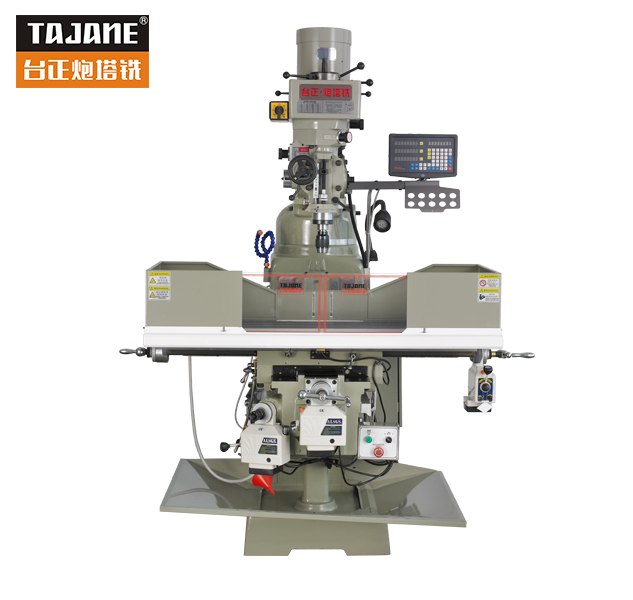

[Company Name] has a rich legacy of engineering excellence, with a strong focus on innovation and customer satisfaction. The company’s commitment to quality and performance has made it a preferred choice for businesses seeking reliable and high-precision CNC machinery. The latest addition to [Company Name]’s impressive portfolio is the Vmc Cnc Milling Machine, which has set new standards in precision engineering and machining capabilities.

The Vmc Cnc Milling Machine from [Company Name] is designed to deliver superior performance and unmatched precision in a wide range of machining applications. The machine is equipped with advanced CNC technology, high-speed spindles, and state-of-the-art control systems, providing users with the flexibility to produce intricate components with uncompromising accuracy. Whether it’s prototyping, batch production, or large-scale manufacturing, the Vmc Cnc Milling Machine offers the versatility and efficiency to meet the most demanding requirements.

One of the key features that sets the Vmc Cnc Milling Machine apart is its robust construction and stability, which are essential for achieving consistent and precise machining results. The machine’s rigid frame and high-quality components ensure vibration-free operation, resulting in exceptional surface finishes and dimensional accuracy. Moreover, the Vmc Cnc Milling Machine is equipped with advanced tool-changing systems and intuitive programming interfaces, enabling operators to streamline their production processes and minimize setup times.

In addition to its superior performance, the Vmc Cnc Milling Machine exemplifies [Company Name]’s commitment to user-friendly design and operational convenience. The machine is ergonomically designed to facilitate ease of access and maintenance, allowing operators to optimize their workflow and maximize productivity. With intuitive controls and exceptional reliability, the Vmc Cnc Milling Machine empowers manufacturers to enhance their machining capabilities with confidence and efficiency.

Furthermore, [Company Name] offers comprehensive training and support services to empower users with the knowledge and skills needed to harness the full potential of the Vmc Cnc Milling Machine. The company’s team of technical experts and application engineers are dedicated to providing ongoing assistance, ensuring that customers can maximize the value of their investment and achieve their production goals effectively.

The introduction of the Vmc Cnc Milling Machine represents a significant milestone for [Company Name], as it showcases the company’s unwavering commitment to advancing the standards of precision engineering and CNC machining technology. By delivering a cutting-edge solution that embodies innovation, reliability, and performance, [Company Name] continues to strengthen its position as a trusted partner for businesses seeking to elevate their manufacturing capabilities.

With its exceptional precision, versatility, and user-centric design, the Vmc Cnc Milling Machine is poised to redefine the benchmarks of excellence in CNC machinery, empowering manufacturers to unleash their full potential and achieve remarkable levels of productivity and quality in their production processes. As the global manufacturing landscape continues to evolve, [Company Name] remains at the forefront of driving progress and delivering solutions that inspire confidence and success in the industry.

Company News & Blog

Top Manual Knee Milling Machine Manufacturer Reveals New Product Line

In the world of manufacturing, precision and efficiency are key components in producing high-quality products. One company that has been at the forefront of providing precision machining solutions is {}. With their expertise in manufacturing knee milling machines, they have been instrumental in helping businesses across various industries meet their production needs.For over two decades, {} has been a leading manufacturer of knee milling machines, catering to the needs of small and medium-sized businesses as well as large-scale manufacturing facilities. Their commitment to providing reliable and durable machines has earned them a stellar reputation in the industry.The {} knee milling machine is designed to deliver exceptional precision and performance, making it an ideal choice for a wide range of machining applications. Whether it's for cutting, drilling, or shaping metal and other materials, this machine offers the versatility and accuracy that businesses demand.One of the key features of the {} knee milling machine is its robust construction, which ensures stability and durability during operation. This machine is built to withstand the rigors of heavy-duty machining, allowing businesses to consistently produce high-quality parts and components with ease.In addition to its solid construction, the {} knee milling machine is also equipped with advanced controls and automation features that streamline the machining process. This not only improves productivity but also reduces the risk of errors, ultimately leading to cost savings for businesses.The precision and reliability of the {} knee milling machine are further enhanced by the company’s commitment to using high-quality components and cutting-edge technology in its manufacturing process. Each machine is meticulously crafted to meet the exacting standards of the industry, ensuring consistent and reliable performance for years to come.Furthermore, {} offers comprehensive support and services to its customers, including installation, training, and maintenance. This ensures that businesses can maximize the potential of their knee milling machines and operate them at peak efficiency.Whether it's for general machining operations or specialized applications, the {} knee milling machine is an invaluable asset for businesses seeking to optimize their manufacturing processes.In a recent statement, a spokesperson for {} expressed the company's dedication to innovation and excellence in providing machining solutions to their customers. "At {}, we are committed to pushing the boundaries of what is possible in precision machining. Our knee milling machines are a testament to this commitment, and we take great pride in helping businesses achieve their production goals with our advanced and reliable machines," said the spokesperson.The spokesperson also emphasized the company’s focus on continuous improvement and adapting to the evolving needs of the manufacturing industry. "As technology and market demands evolve, we are constantly refining and expanding our product offerings to ensure that our customers have access to the best machining solutions available. We remain dedicated to providing cutting-edge technology and exceptional quality in every machine we produce," the spokesperson added.Looking ahead, {} remains poised to uphold its position as a leading manufacturer of knee milling machines, with a steadfast dedication to providing innovative solutions that empower businesses to thrive in a competitive manufacturing landscape. With their unwavering commitment to excellence and customer satisfaction, {} is set to continue making a significant impact in the industry for years to come.

Top Vertical Machining Center Machine Factories in China

China Vertical Machining Center Machine Factories, known for their high-quality precision machining equipment, are making a significant impact in the global manufacturing industry. With a focus on innovation and advanced technology, these factories are consistently delivering cutting-edge solutions to their clients. One of the leading factories in this sector is located in the Hubei province of China. With state-of-the-art facilities and a team of highly skilled engineers and technicians, this factory has established itself as a key player in the vertical machining center machine industry. The company prides itself on its ability to provide customized solutions to meet the specific needs of its clients, and its dedication to quality and precision has earned it a stellar reputation in the market.The factory specializes in the production of a wide range of vertical machining center machines, including 3-axis, 4-axis, and 5-axis models. These machines are widely used in industries such as aerospace, automotive, electronics, and medical equipment manufacturing. The company's commitment to research and development has enabled it to stay ahead of the competition and consistently deliver cutting-edge solutions to its clients.In addition to its strong focus on product innovation, the company also places a high priority on customer satisfaction. It works closely with its clients to understand their specific needs and requirements, and then tailors its solutions to meet those needs. This customer-centric approach has helped the company build long-lasting relationships with its clients and has contributed to its continued success in the industry.One of the key factors that sets this factory apart from its competitors is its commitment to quality control. The company adheres to strict quality standards at every stage of the manufacturing process, from design and prototyping to production and testing. This ensures that the final products meet the highest quality and performance standards, giving clients the peace of mind that they are investing in reliable and durable equipment.Furthermore, the factory is also dedicated to sustainability and environmental responsibility. It has implemented eco-friendly practices in its manufacturing processes, such as the use of energy-efficient equipment and the proper disposal of waste materials. As a result, the company has earned a reputation for being a responsible corporate citizen in the industry.In addition to its strong domestic presence, this factory has also expanded its reach to the international market. It has successfully exported its vertical machining center machines to clients around the world, and its products have been well-received for their quality and reliability. The company's global expansion efforts have helped it establish a strong foothold in the global manufacturing industry, and it continues to seek new opportunities for growth and expansion.Looking ahead, this factory remains committed to its core values of innovation, quality, and customer satisfaction. It continues to invest in research and development to stay ahead of the curve in terms of technological advancements, and it remains dedicated to providing the best possible solutions to its clients. With a strong foundation and a clear vision for the future, this factory is poised to continue its success and make a lasting impact in the vertical machining center machine industry.

Vertical Machining Center Factory in China: Production Process and Operations

China Vertical Machining Center Working Factory (CVMCWF), located in the heart of China's industrial sector, is a leading manufacturer of state-of-the-art machining centers. The company has built a strong reputation for producing high-precision, reliable, and cost-effective machining solutions for a wide range of industries, including aerospace, automotive, electronics, and medical devices.With a strong focus on innovation and continuous improvement, CVMCWF has invested heavily in research and development to stay ahead of the competition. The company's team of experienced engineers and technicians are constantly pushing the boundaries of machining technology, developing cutting-edge solutions that meet the evolving needs of its customers.One of the key factors behind CVMCWF's success is its commitment to quality. The company operates a state-of-the-art manufacturing facility equipped with advanced production machinery and strict quality control processes. Every machining center produced by CVMCWF undergoes rigorous testing to ensure it meets the highest standards of performance and reliability.In addition to its commitment to quality, CVMCWF is also dedicated to providing exceptional customer service. The company's team of sales and support professionals work closely with customers to understand their specific needs and provide tailored solutions to meet their requirements. CVMCWF's after-sales service team is also on hand to provide technical support and maintenance to ensure its customers get the most out of their machining centers.Recently, CVMCWF made headlines with the launch of its latest vertical machining center, the VMC-8000. This cutting-edge machine is designed to deliver unrivaled precision and performance, making it the ideal choice for high-precision machining applications. Equipped with a powerful spindle, advanced control system, and a rigid, stable structure, the VMC-8000 is capable of tackling the most demanding machining tasks with ease.To demonstrate the capabilities of the VMC-8000, CVMCWF recently hosted a live demonstration at its factory. The event was attended by industry professionals, customers, and media representatives who were given the opportunity to see the machine in action. The demonstration showcased the VMC-8000's impressive capabilities, including its high-speed machining, exceptional accuracy, and effortless performance.During the demonstration, CVMCWF's team of engineers and technicians provided detailed insights into the machine's design, features, and capabilities. Attendees were given the opportunity to ask questions and interact with the CVMCWF team, gaining valuable knowledge about the VMC-8000 and its potential applications.The live demonstration was met with widespread acclaim, with many attendees expressing their admiration for the VMC-8000's performance and precision. The event served as a testament to CVMCWF's commitment to innovation and its ability to deliver cutting-edge machining solutions that meet the evolving needs of the industry.Looking ahead, CVMCWF is poised to continue its success, with a strong focus on further innovation and expansion. The company is actively exploring new technologies and techniques to further enhance the performance of its machining centers, and is committed to providing exceptional products and services to its customers.As CVMCWF continues to push the boundaries of machining technology, it is cementing its position as a global leader in the industry. With a steadfast dedication to quality, innovation, and customer satisfaction, CVMCWF is well-positioned to shape the future of machining technology and continue to provide cutting-edge solutions to its customers around the world.

Top Small Machining Center for Precision Milling and Drilling

The demand for high-precision, small machining centers has been increasing in the manufacturing industry due to the growing need for advanced technology in production processes. As a response to this demand, a leading manufacturer {} has recently introduced a state-of-the-art small machining center that is set to revolutionize the industry.The new small machining center, known as the MiniPro 200, is a compact and highly efficient machine that is designed to meet the needs of small to medium-sized manufacturing companies. It is equipped with advanced features and cutting-edge technology that allows for precise and accurate machining of various materials, including metals, plastics, and composites.One of the key features of the MiniPro 200 is its high-speed spindle, which is capable of achieving speeds of up to 20,000 RPM. This ensures that the machine is able to perform quick and precise machining operations, resulting in higher productivity and efficiency. Additionally, the machine is equipped with a tool changer that can hold up to 12 tools, allowing for seamless and uninterrupted machining processes.Another notable feature of the MiniPro 200 is its compact design, which makes it ideal for small manufacturing facilities with limited space. Despite its small footprint, the machine offers a spacious work area and a sturdy construction that ensures stability and accuracy during machining operations.In addition to its advanced features, the MiniPro 200 is also equipped with a user-friendly control interface that allows for easy and intuitive operation. This ensures that even inexperienced operators can quickly learn how to use the machine, reducing the need for extensive training and maximizing productivity.According to the company spokesperson, the MiniPro 200 is the result of years of research and development, and it represents a significant advancement in small machining center technology. "We are proud to introduce the MiniPro 200 to the market, as we believe it will set a new standard for small machining centers," the spokesperson stated. "Its advanced features and compact design make it a game-changer for small and medium-sized manufacturing companies looking to enhance their production capabilities."The introduction of the MiniPro 200 comes at a time when the manufacturing industry is experiencing a growing need for advanced machining technology. With the rise of Industry 4.0 and the increasing demand for high-precision components, small machining centers have become essential tools for manufacturers looking to stay competitive in the market.As a leading manufacturer in the industry, {} has established itself as a trusted provider of high-quality machining solutions. With a strong focus on innovation and customer satisfaction, the company has consistently delivered cutting-edge machines that meet the evolving needs of the manufacturing sector.The introduction of the MiniPro 200 is a testament to {}'s commitment to providing advanced and reliable machining solutions to its customers. With its advanced features, compact design, and user-friendly interface, the MiniPro 200 is set to make a significant impact in the industry and help manufacturers achieve new levels of productivity and precision.In conclusion, the introduction of the MiniPro 200 small machining center by {} marks a significant milestone in the manufacturing industry. With its advanced features, compact design, and user-friendly interface, the machine is set to revolutionize small to medium-sized manufacturing companies, helping them enhance their production capabilities and stay ahead of the competition. As the demand for high-precision machining technology continues to grow, the MiniPro 200 represents a cutting-edge solution that will help manufacturers meet the evolving needs of the industry.

Top Vertical Machining Center Machine Manufacturer from China

China Vertical Machining Center Machine Manufacturer has recently made waves in the manufacturing industry with its cutting-edge technology and innovative solutions. This company has been at the forefront of the machining industry for over a decade, and has continued to push the boundaries of what is possible in the world of vertical machining.The company specializes in the design, development, and production of vertical machining centers, which are essential components of modern manufacturing processes. These machines are used to create precision parts and components for a wide range of industries, including automotive, aerospace, electronics, and more.One of the key features that sets China Vertical Machining Center Machine Manufacturer apart from its competitors is its commitment to innovation. The company is constantly researching and developing new technologies to improve the performance and reliability of its machines. This dedication to innovation has allowed China Vertical Machining Center Machine Manufacturer to stay ahead of the curve and provide its customers with the most advanced solutions available on the market.In addition to its focus on innovation, China Vertical Machining Center Machine Manufacturer places a strong emphasis on quality and reliability. The company's machines are built to the highest standards, using top-quality materials and components to ensure long-lasting performance. This commitment to quality has earned China Vertical Machining Center Machine Manufacturer a reputation for producing some of the most reliable and durable machines in the industry.Furthermore, China Vertical Machining Center Machine Manufacturer is known for its exceptional customer service and support. The company's team of experts is always available to provide technical assistance, training, and troubleshooting to ensure that its customers get the most out of their machines. This level of support has helped China Vertical Machining Center Machine Manufacturer build strong, long-lasting relationships with its customers, who continue to turn to the company for all their machining needs.As a result of its dedication to innovation, quality, and customer service, China Vertical Machining Center Machine Manufacturer has become a trusted partner for companies around the world. Its machines are being used in a wide range of industries, helping businesses improve their production processes and stay ahead of the competition.Looking ahead, China Vertical Machining Center Machine Manufacturer shows no signs of slowing down. The company is constantly looking for new ways to advance its technology and expand its product offerings, ensuring that it remains a leader in the machining industry for many years to come.In conclusion, China Vertical Machining Center Machine Manufacturer has established itself as a leading force in the manufacturing industry, thanks to its commitment to innovation, quality, and customer service. With a focus on delivering cutting-edge technology and reliable solutions, the company continues to set the bar for excellence in the world of vertical machining. As the industry evolves, China Vertical Machining Center Machine Manufacturer remains dedicated to providing its customers with the best possible machines and support, ensuring that it will remain a top choice for companies looking to take their manufacturing processes to the next level.

Vertical Knee CNC Machine Factories - Your Guide to CNC Supra Machines

The demand for high-quality and reliable computer numerical control (CNC) machines has been on the rise in various industries. CNC machines are an essential part of the manufacturing process, allowing businesses to produce precision parts and components with ease. In line with this, several factories have been making strides in the production of top-notch CNC machines, and one such factory is {}.{} is a renowned manufacturer of CNC machines, known for its high-performance products and cutting-edge technology. The company has been at the forefront of innovation in the CNC machine industry, consistently delivering state-of-the-art solutions to its clients. {} offers a wide range of CNC machines, including vertical knee CNC machines that are designed to meet the diverse needs of its customers.The company's vertical knee CNC machines have gained a reputation for their robust construction, precision engineering, and user-friendly interface. These machines are capable of handling a variety of tasks, from intricate milling to heavy-duty drilling, making them a versatile choice for businesses in the manufacturing sector. With a focus on quality and efficiency, {} has positioned itself as a reliable source for CNC machines that deliver exceptional performance.In a recent development, {} has expanded its production capacity for vertical knee CNC machines, in response to the growing demand from its global clientele. The factory has invested in cutting-edge technology and modern manufacturing processes to enhance its production capabilities. By doing so, {} aims to streamline its operations and meet the increasing market demand for its CNC machines.The expansion of {}'s factory aligns with the company's commitment to delivering superior products and services to its customers. With an emphasis on quality control and precision engineering, {} ensures that each CNC machine that rolls out of its factory meets the highest standards of performance and reliability. This dedication to excellence has earned {} a loyal customer base and solidified its position as a leading manufacturer of CNC machines.Furthermore, {}'s factory expansion is expected to create new job opportunities and stimulate economic growth in the region. The investment in state-of-the-art manufacturing facilities will not only benefit the company but also contribute to the local community by generating employment and fostering talent development in the manufacturing sector.As the demand for CNC machines continues to grow, {} remains committed to staying ahead of the curve by introducing new technologies and advancing its production capabilities. By expanding its factory and investing in modern manufacturing infrastructure, the company aims to reinforce its position as a top-tier manufacturer of CNC machines, serving the needs of an ever-evolving market.In conclusion, the expansion of {}'s factory for the production of vertical knee CNC machines signifies the company's dedication to meeting the rising demand for high-quality CNC solutions. With its unwavering commitment to innovation and excellence, {} is well-positioned to cater to the needs of businesses across various industries, providing them with advanced CNC machines that are built to deliver superior performance and reliability. The factory expansion not only demonstrates {}'s growth and success but also its contribution to the advancement of the manufacturing sector.

Discover the Benefits of a Gantry Type Vertical Machining Center for Your Business

Gantry Type Vertical Machining Center has been making headlines in the manufacturing industry due to its cutting-edge technology and innovative features. This state-of-the-art machine tool has been engineered to deliver superior performance, precision, and efficiency, making it a game-changer in the world of machining.The Gantry Type Vertical Machining Center is designed and manufactured by {} - a leading global provider of advanced machining solutions. With over 50 years of experience in the industry, {} has established a reputation for excellence and innovation, consistently pushing the boundaries of what is possible in manufacturing technology.The Gantry Type Vertical Machining Center is a testament to {}'s commitment to delivering cutting-edge solutions that meet the evolving needs of the industry. It is equipped with a high-speed spindle and advanced control system, allowing for rapid material removal and exceptional surface finish. The machine's gantry structure provides exceptional rigidity and stability, ensuring precision and accuracy in every operation.One of the key features of the Gantry Type Vertical Machining Center is its versatility. It is capable of handling a wide range of materials, from aluminum and steel to titanium and composites, making it an ideal solution for a variety of applications. Whether it's aerospace components, automotive parts, or mold and die manufacturing, this machining center delivers the performance and reliability required to meet the most demanding production requirements.In addition to its exceptional performance, the Gantry Type Vertical Machining Center is designed for ease of use and maintenance. The ergonomic design and intuitive controls make it easy for operators to set up and operate the machine, while the modular construction simplifies maintenance and servicing, reducing downtime and ensuring maximum productivity.Furthermore, the Gantry Type Vertical Machining Center is equipped with advanced automation and connectivity features, allowing for seamless integration into smart manufacturing environments. With support for industry-standard protocols and communication interfaces, the machine can be easily integrated into digital manufacturing systems, enabling real-time monitoring, data analysis, and optimization of production processes.The Gantry Type Vertical Machining Center is also designed with sustainability in mind. With energy-efficient components and intelligent power management systems, the machine minimizes energy consumption without compromising performance, reducing both operating costs and environmental impact.The introduction of the Gantry Type Vertical Machining Center represents a significant milestone for {} and the manufacturing industry as a whole. It embodies the company's ongoing commitment to innovation, quality, and customer satisfaction, setting new standards for precision machining and production efficiency.With its advanced technology, versatility, and sustainability, the Gantry Type Vertical Machining Center is poised to revolutionize the way manufacturers approach machining and production. As industry demands continue to evolve, this innovative machine tool will play a key role in shaping the future of manufacturing, helping businesses stay competitive and thrive in a rapidly changing market.As {} continues to push the boundaries of what is possible in machining technology, the Gantry Type Vertical Machining Center stands as a testament to the company's dedication to excellence and its relentless pursuit of innovation. With its exceptional performance, versatility, and sustainability, this cutting-edge machine tool is set to redefine the future of manufacturing, empowering businesses to achieve new levels of productivity, precision, and success.

New Study Reveals VMC-1890's Impact on Market Trends

VMC-1890, a cutting-edge machining center, has been making waves in the manufacturing industry with its high precision and efficiency. Developed by a leading machinery manufacturing company, this innovative machine has become a game-changer for companies looking to streamline their production processes and improve overall productivity.The VMC-1890 is equipped with state-of-the-art technology and features a large working area, making it suitable for a wide range of machining applications. Its high-speed spindle and advanced tool changer allow for quick and precise machining, while its sturdy and stable construction ensures consistent and reliable performance.With the ability to handle a variety of materials, including metal, plastic, and composite, the VMC-1890 is a versatile solution for manufacturers across different sectors. Its advanced control system and user-friendly interface make operation and programming straightforward, minimizing downtime and increasing throughput.Furthermore, the VMC-1890 is designed with energy efficiency in mind, reducing power consumption and operating costs for companies. Its environmentally friendly features align with the growing demand for sustainable manufacturing practices, enhancing its appeal to businesses looking to reduce their carbon footprint.In addition to its impressive technical specifications, the VMC-1890 is backed by comprehensive customer support and a team of experienced engineers who provide ongoing maintenance and technical assistance. This ensures that businesses can maximize the performance and lifespan of their investment, contributing to long-term success and growth.Since its launch, the VMC-1890 has garnered positive feedback from businesses that have incorporated it into their production processes. Many have reported significant improvements in productivity, quality, and overall efficiency, leading to cost savings and enhanced competitiveness in the market."We invested in the VMC-1890 to upgrade our machining capabilities, and it has exceeded our expectations in terms of performance and reliability," said a satisfied customer. "It has allowed us to fulfill orders faster and with greater precision, giving us a competitive edge in our industry."The success of the VMC-1890 has not gone unnoticed, with an increasing number of companies showing interest in integrating this cutting-edge machining center into their operations. Its reputation for superior quality and its ability to deliver consistent results have made it a sought-after solution for businesses striving for operational excellence.With the manufacturing industry evolving at a rapid pace, the VMC-1890 has emerged as a leading choice for companies looking to modernize their production capabilities and stay ahead of the competition. Its combination of advanced technology, versatility, and reliability positions it as a valuable asset for businesses seeking to optimize their manufacturing processes and achieve sustainable growth.In conclusion, the VMC-1890, developed by a leading machinery manufacturing company, stands out as a top-tier solution for businesses aiming to enhance their production efficiency and output quality. Its cutting-edge technology, user-friendly operation, and robust construction make it an ideal choice for a wide range of machining applications. As the manufacturing industry continues to evolve, the VMC-1890 has proven to be a game-changer, empowering businesses to achieve their goals and succeed in today's competitive market.

Advanced Gantry Machining: A Comprehensive Guide to Precision Machining Techniques

In the world of manufacturing and production, precision and efficiency are key factors in achieving success. This is where gantry machining plays a crucial role. Gantry machining, also known as gantry milling, is a process that involves the use of a gantry-style design to carry out various machining operations on a workpiece. This method is often used in industries such as aerospace, automotive, and defense, where high precision and intricate machining is required.One company that specializes in providing top-notch gantry machining services is {}. With years of experience and expertise in the field, {} has established itself as a leading player in the industry, offering a wide range of machining solutions to meet the diverse needs of its clients. From small-scale prototyping to large-scale production runs, {} has the capabilities to handle projects of all sizes and complexities.The gantry machining process involves the use of a gantry-style machine, which is essentially a large, rigid structure that spans the entire work area. This design provides the machine with stability and precision, allowing it to carry out intricate machining operations with utmost accuracy. The workpiece is securely held in place, while the cutting tools are guided by computer numerical control (CNC) to perform the necessary operations, such as drilling, milling, and cutting.One of the key advantages of gantry machining is its ability to handle large and heavy workpieces with ease. This makes it an ideal choice for industries that deal with oversized components, such as the aerospace and automotive sectors. Additionally, gantry machining is known for its high level of repeatability and consistency, ensuring that every part produced meets the specified tolerances and quality standards.In addition to its machining capabilities, {} also offers a range of value-added services to complement its gantry machining processes. These include engineering support, material sourcing, and quality inspection, among others. This comprehensive approach allows {} to provide its clients with a one-stop solution for all their machining needs, from the initial design phase to the final production stage.Furthermore, {} places a strong emphasis on continuous improvement and innovation, constantly investing in the latest technologies and processes to stay ahead of the curve. This commitment to staying at the forefront of the industry has allowed {} to expand its capabilities and take on increasingly complex projects, further solidifying its position as a trusted partner for its clients.As the demand for high-precision machining continues to rise, {} remains dedicated to providing top-quality gantry machining solutions to its clients across various industries. With its state-of-the-art facilities, experienced team, and unwavering commitment to excellence, {} is well-equipped to handle the evolving needs of the manufacturing sector and contribute to the success of its clients.In conclusion, gantry machining plays a crucial role in the manufacturing world, and {} has proven to be a leader in providing top-notch gantry machining services. With its advanced capabilities, comprehensive solutions, and dedication to innovation, {} is well-poised to meet the diverse and evolving needs of its clients, setting the standard for excellence in the field of machining.

Large Vertical Turning Center Factory in China: What You Need to Know

China Large Vertical Turning Center Factory, a leading manufacturer of CNC machine tools, recently announced the opening of a new state-of-the-art production facility. This new factory is dedicated to the production of large vertical turning centers, which are essential for the machining of large and heavy workpieces. The facility is equipped with the latest technology and is expected to significantly increase the company's production capacity.The new factory is strategically located in a manufacturing hub, which allows for easy access to raw materials and transportation. The facility covers a vast area, with separate sections for manufacturing, assembly, quality control, and testing. The company has invested heavily in advanced machinery and equipment to ensure that the production process is efficient and of the highest quality.Large vertical turning centers are crucial for industries such as aerospace, automotive, energy, and heavy machinery. These machines are used for turning, milling, and drilling large workpieces with high precision and accuracy. The demand for large vertical turning centers has been steadily increasing, and China Large Vertical Turning Center Factory has recognized the opportunity to expand its production capacity to meet this growing demand.The company's commitment to innovation and continuous improvement is reflected in the design and layout of the new factory. The production process is highly automated, with a focus on streamlining operations and maximizing efficiency. This approach not only ensures high-quality products but also reduces lead times, allowing the company to better serve its customers.China Large Vertical Turning Center Factory has a strong focus on quality control and testing. The new facility is equipped with advanced testing equipment to ensure that every machine meets the highest standards of accuracy and performance. Additionally, the company has implemented strict quality control processes at every stage of the production process to identify and address any issues proactively.Moreover, the company has a team of highly skilled engineers and technicians who are responsible for the design, development, and production of the large vertical turning centers. These professionals have undergone extensive training and possess a wealth of experience in the field of CNC machine tools. Their expertise and dedication are instrumental in ensuring that the products manufactured at the new facility are of the highest quality.Furthermore, China Large Vertical Turning Center Factory is committed to environmental sustainability. The new facility has been designed with eco-friendly features, such as energy-efficient machinery and waste management systems. The company understands the importance of minimizing its environmental impact and is constantly seeking ways to reduce its carbon footprint.The opening of the new factory is a significant milestone for China Large Vertical Turning Center Factory. It represents the company's dedication to growth and innovation in the field of CNC machine tools. By increasing its production capacity for large vertical turning centers, the company aims to better serve its customers and meet the growing demand for these essential machines.In conclusion, the opening of the new state-of-the-art production facility is a testament to China Large Vertical Turning Center Factory's commitment to excellence and innovation. The company's investment in advanced technology and infrastructure will undoubtedly strengthen its position as a leading manufacturer of CNC machine tools. With the increased production capacity, the company is well-positioned to meet the growing demand for large vertical turning centers and continue to serve its customers with high-quality products.