Precision Profile Milling Machine for High Efficiency Machining

By:Admin

In the manufacturing industry, precision and efficiency are key components in producing high-quality products. With the advancements in technology, companies are constantly seeking innovative solutions to improve their manufacturing processes. One such solution that has gained traction in the industry is the Profile Milling Machine.

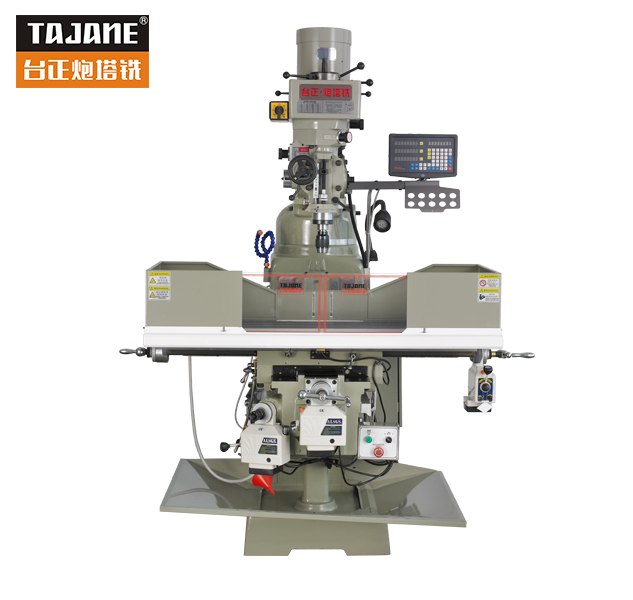

The Profile Milling Machine, offered by a leading manufacturing company, is a state-of-the-art machine tool that is designed to precisely shape and cut complex profiles on various workpieces. This cutting-edge machine has revolutionized the way manufacturers produce intricate components, allowing them to achieve high levels of precision and accuracy.

With a strong focus on innovation and continuous improvement, the manufacturing company has integrated the Profile Milling Machine into their production process. The machine has enabled them to streamline their manufacturing operations and meet the increasing demand for high-precision components across various industries.

The Profile Milling Machine is equipped with advanced features such as high-speed spindle, multi-axis control, and automatic tool change, which allows for quick and precise machining of complex profiles. This enables the company to achieve tight tolerances and superior surface finishes, giving them a competitive edge in the market.

Moreover, the machine is capable of handling a wide range of materials, including aluminum, steel, and composites, further expanding the company's capabilities in producing diverse components for different applications. This versatility has allowed them to cater to the unique requirements of their customers and deliver custom solutions that meet their specific needs.

In addition to its precision and versatility, the Profile Milling Machine is also renowned for its efficiency. The company has reported significant reductions in lead times and production costs since implementing the machine into their workflow. The machine's high-speed machining capabilities and optimized tool paths have enabled the company to improve their overall productivity and meet tight production deadlines.

Furthermore, the Profile Milling Machine has enhanced the company's ability to undertake complex projects that were previously deemed challenging. Its advanced programming and simulation software allow for the seamless execution of intricate machining operations, resulting in the production of complex and high-precision components with ease.

The company's commitment to quality and innovation, coupled with the adoption of the Profile Milling Machine, has garnered positive feedback from their customers. The machine has enabled the company to consistently deliver superior products that meet strict quality standards, earning them a reputation for reliability and excellence in the industry.

Looking ahead, the company aims to further leverage the capabilities of the Profile Milling Machine to expand their product offerings and enter new markets. With a focus on research and development, they are exploring new applications and techniques to maximize the potential of the machine and stay ahead of the competition.

In conclusion, the Profile Milling Machine has proven to be a game-changer for the manufacturing company, elevating their capabilities in precision machining and setting new benchmarks for efficiency. As they continue to harness the power of this cutting-edge technology, they are poised to drive innovation and deliver exceptional value to their customers in the ever-evolving manufacturing landscape.

Company News & Blog

High-precision Gantry Mill: A Powerful Industrial Machine for Your Workshop

Gantry Mill, a leading manufacturer in the field of industrial machinery, has recently unveiled their latest innovation in the world of machining technology. This new Gantry Mill is set to revolutionize the way large-scale machining is done, providing improved accuracy, efficiency, and versatility compared to previous models.With over 30 years of experience in the industry, Gantry Mill has established a solid reputation for delivering high-quality machinery that meets the needs of a wide range of industrial applications. Their team of engineers and designers have been dedicated to developing cutting-edge solutions that push the boundaries of what is possible in the world of machining.The new Gantry Mill is a testament to their commitment to innovation and excellence. It features a robust and rigid structure, designed to handle heavy-duty machining operations with ease. The machine also boasts a high-performance spindle, capable of delivering exceptional cutting power and precision. This allows for the machining of a variety of materials, including metals, plastics, and composites, with uncompromising accuracy.One of the key features of the new Gantry Mill is its advanced control system, which allows for seamless integration with CAD/CAM software. This enables operators to easily program and execute complex machining tasks with minimal manual intervention, resulting in higher efficiency and productivity. Additionally, the machine is equipped with state-of-the-art automation options, such as tool changers and material handling systems, that further enhance its capabilities.The versatility of the Gantry Mill is another standout feature. Its large working envelope and multi-axis capability make it suitable for a wide range of machining applications, including milling, drilling, boring, and tapping. This makes it an ideal choice for industries such as aerospace, automotive, energy, and defense, where precision and reliability are of utmost importance.In addition to its technical prowess, the new Gantry Mill also prioritizes operator safety and ease of use. It is equipped with comprehensive safety features and ergonomic design elements to ensure a secure working environment for the machine operators. This, combined with intuitive controls and user-friendly interface, makes the machine accessible to operators of varying skill levels.Moreover, Gantry Mill offers comprehensive customer support and training programs to ensure that their clients can make the most of their investment. This includes on-site installation and commissioning, as well as ongoing maintenance and technical assistance. With a global network of service centers and spare parts warehouses, Gantry Mill is dedicated to providing prompt and reliable support to their customers, wherever they may be located.Overall, the new Gantry Mill represents a significant leap forward in the world of machining technology. Its advanced capabilities, combined with Gantry Mill's reputation for quality and support, make it a compelling choice for companies looking to elevate their machining operations to new heights. As the industrial landscape continues to evolve, Gantry Mill remains committed to pushing the boundaries of what is possible, and their latest innovation is a testament to this enduring spirit of innovation and excellence.

Top Vertical Milling Centre Machine Manufacturers in China

China Vertical Milling Centre Machine Manufacturers, together with their company introduction, are making significant strides in the manufacturing industry. The manufacturing industry in China has seen a surge in demand for high-quality milling machines, and China Vertical Milling Centre Machine Manufacturers have risen to the occasion by providing innovative and reliable solutions.One of the key players in the industry is a leading manufacturer of vertical milling centre machines in China. With years of experience and expertise in the field, they have established a strong reputation for delivering top-notch products and services to their clients worldwide. Their state-of-the-art manufacturing facilities and advanced technology have positioned them as a formidable force in the industry.The company's vertical milling centre machines are designed to meet the diverse needs of their clients. Whether it's for precision machining, large-scale production, or custom applications, their machines are built to deliver consistent performance and exceptional accuracy. The company prides itself on their commitment to quality, reliability, and customer satisfaction.In addition to their cutting-edge machines, the company also offers a wide range of services to support their clients throughout the entire manufacturing process. From initial consultation and design to installation and after-sales support, their team of experts is dedicated to ensuring that their clients' needs are met with the highest level of professionalism and proficiency.Furthermore, the company's dedication to research and development has led to continuous advancements in their products and services. By staying at the forefront of technological innovation, they are able to provide their clients with the most advanced solutions for their machining needs. This commitment to innovation has earned them a solid reputation as a reliable and forward-thinking manufacturer in the industry.Moreover, the company has also made significant efforts to streamline their production processes and enhance their manufacturing capabilities. By investing in cutting-edge equipment and implementing efficient production methods, they have been able to increase their capacity and improve lead times without compromising on quality. This has allowed them to better meet the growing demand for their products and strengthen their position in the market.As part of their global expansion strategy, the company has also established strong partnerships and collaborations with clients and distributors around the world. This has allowed them to broaden their reach and deliver their high-quality products to a wider audience. It has also provided them with valuable insights into the unique needs and preferences of different markets, enabling them to tailor their products and services accordingly.Looking ahead, China Vertical Milling Centre Machine Manufacturers are poised to continue their upward trajectory in the industry. With their unwavering commitment to excellence, innovation, and customer satisfaction, they are well-positioned to meet the evolving needs of the manufacturing industry and solidify their standing as a leading provider of vertical milling centre machines in China and beyond.In conclusion, China Vertical Milling Centre Machine Manufacturers, with their extensive experience, cutting-edge technology, and unwavering dedication to quality, are making significant contributions to the manufacturing industry. By consistently delivering top-notch products and services, they have earned the trust and confidence of their clients and established themselves as a force to be reckoned with in the market. As they continue to innovate and expand their global presence, they are well-positioned to shape the future of the industry and set new standards for excellence in manufacturing.

Benchtop Machining Center: Enhancing Precision and Efficiency

Title: Innovation and Precision: New Benchtop Machining Center Revolutionizes ManufacturingIntroduction:In today's rapidly evolving manufacturing landscape, businesses are constantly seeking innovative solutions that enhance efficiency, precision, and productivity. With this in mind, a renowned company announces the launch of their groundbreaking Benchtop Machining Center. Leveraging cutting-edge technology and an unwavering commitment to quality, this state-of-the-art machine is set to revolutionize the manufacturing sector. Combining speed, accuracy, and versatility, the Benchtop Machining Center promises to be a game-changer in the industry, empowering businesses with the tools they need to succeed in an increasingly competitive market.[Company Name], born out of years of experience and a dedication to excellence, has paved the way for advanced machining technology. Their ethos centers on delivering tools that exceed customer expectations and enhance manufacturing processes across a wide range of industries. With their Benchtop Machining Center, [Company Name] aims to equip businesses with a transformative solution that accelerates productivity, increases accuracy, and reduces downtime, all while maintaining unmatched levels of quality.Streamlining Manufacturing Processes:The Benchtop Machining Center boasts a wide array of features meticulously designed to optimize manufacturing processes. One of its standout attributes is its ability to perform multiple operations simultaneously, reducing the need for manual intervention and significantly speeding up production cycles. Combining milling, drilling, and precision turning in a single unit, this state-of-the-art machine ensures maximum versatility and cost-efficiency for businesses of all sizes.Unmatched Precision and Accuracy:Precision is the foundation of manufacturing excellence, and the Benchtop Machining Center offers unmatched accuracy and repeatability. Equipped with advanced computer numerical control (CNC) systems, the machine ensures that every cut, drill, or turn is executed with meticulous precision, resulting in consistently high-quality parts. This level of accuracy not only enhances product quality but also minimizes material waste, leading to significant cost savings for manufacturers.Intuitive User Interface:Recognizing the importance of user-friendly interfaces in optimizing productivity, [Company Name] has developed an intuitive control system for the Benchtop Machining Center. Featuring a user-friendly touchscreen panel, operators can effortlessly navigate through the machine's various functions, enabling seamless operations and reducing potential human errors. Additionally, the control system includes built-in safety features that prioritize operator well-being, further enhancing the overall user experience.Quality Engineering:The Benchtop Machining Center is the result of meticulous engineering and rigorous quality control. Employing high-quality materials and cutting-edge manufacturing techniques, each unit is built to withstand demanding operational environments. Robustness and reliability are key attributes of this machine, ensuring that manufacturers can rely on the Benchtop Machining Center for consistently outstanding performance.Versatility and Adaptability:Recognizing the diverse needs of modern manufacturers across industries, the Benchtop Machining Center offers maximum versatility and adaptability. With its modular design, the machine can be easily customized and upgraded to meet evolving manufacturing requirements. From small fabrication workshops to large-scale manufacturing facilities, the Benchtop Machining Center can be tailored to fit varying demands, ensuring that the investment remains future-proof.Conclusion:As the manufacturing sector continues to evolve and innovate, the Benchtop Machining Center introduces a new era of precision, speed, and versatility. [Company Name] intends to redefine manufacturing standards by empowering businesses with this state-of-the-art machine. With its comprehensive range of features, unparalleled precision, and user-friendly interface, the Benchtop Machining Center is poised to catalyze productivity and efficiency for manufacturers worldwide. In an increasingly competitive market, this innovative solution will undoubtedly set new benchmarks for manufacturing excellence, solidifying [Company Name]'s position as a leader in the industry.

Top Large Vertical Turning Center Factories in China

China Large Vertical Turning Center Factories Boosting Manufacturing EfficiencyWith the rapid advancement of technology and the increasing demand for high-quality manufacturing equipment, China has seen a significant rise in the development of Large Vertical Turning Center factories in recent years. These factories are pushing the boundaries of manufacturing efficiency and innovation, and are becoming a key player in the global manufacturing industry.One of the leading companies in this sector in China is {}. This company has been a driving force in the development and production of Large Vertical Turning Centers, and has been making significant contributions to the manufacturing industry in China and beyond.The company’s Large Vertical Turning Centers are known for their high precision, reliability, and efficiency, making them ideal for a wide range of applications in industries such as aerospace, automotive, energy, and defense. With a strong focus on research and development, {} has been able to stay ahead of the curve in terms of innovation and technological advancement in the Large Vertical Turning Center industry.One of the key factors that sets {} apart from its competitors is its commitment to quality. The company has implemented strict quality control measures throughout the manufacturing process, ensuring that each Large Vertical Turning Center that comes out of its factories meets the highest standards of excellence. This dedication to quality has earned {} a stellar reputation in the industry and has made its products highly sought after by manufacturers around the world.In addition to its focus on quality, {} is also committed to sustainability and environmental responsibility. The company has made significant investments in developing eco-friendly manufacturing processes and has implemented measures to reduce its carbon footprint. This commitment to sustainability has not only had a positive impact on the environment, but has also helped {} attract environmentally conscious customers who are looking for manufacturing equipment that is both efficient and eco-friendly.Another key aspect of {}’s success is its dedication to customer satisfaction. The company takes pride in providing exceptional customer service and support, and is always willing to go the extra mile to ensure that its customers are fully satisfied with their Large Vertical Turning Centers. This commitment to customer satisfaction has helped {} build long-lasting relationships with its clients and has played a crucial role in the company’s continued success in the industry.In order to meet the growing demand for its Large Vertical Turning Centers, {} has been expanding its production capacity in China. The company has recently invested in state-of-the-art manufacturing facilities and has increased its workforce to ramp up production. These efforts have enabled {} to increase its output and fulfill large orders in a timely manner, solidifying its position as a leading supplier of Large Vertical Turning Centers in the global market.Looking ahead, {} remains committed to pushing the boundaries of manufacturing efficiency and innovation. The company has a strong pipeline of new products in development and is constantly exploring new technologies and methods to improve its manufacturing processes. With its unwavering dedication to quality, sustainability, and customer satisfaction, {} is well poised to continue its success and make a significant impact on the global manufacturing industry for years to come.

Exploring the Advantages of Horizontal Knee Milling Machines in China

China Horizontal Knee Milling Machine Revolutionizes Manufacturing IndustryIn today's rapidly evolving manufacturing landscape, Chinese engineering and technological advancements continue to be at the forefront. One such innovation making headlines is the groundbreaking China Horizontal Knee Milling Machine, which is experiencing significant demand and transforming the manufacturing industry. With its precision, efficiency, and versatility, this cutting-edge milling machine has the potential to revolutionize various sectors, from automotive and aerospace to electronics and energy.The China Horizontal Knee Milling Machine, produced by an industry-leading manufacturing company, is built on years of research and development. The company has continually strived to develop and enhance their milling machines, combining state-of-the-art technology with a deep understanding of industry demands. This dedication has catapulted them to the forefront of the global market, as they continue to innovate and adapt to industry requirements.One of the key features that sets the China Horizontal Knee Milling Machine apart is its exceptional precision. The machine is equipped with advanced sensors and controls, ensuring precise and accurate milling operations. This level of precision is especially important in sectors where tight tolerances are crucial, such as aerospace and medical device manufacturing. With this revolutionary milling machine, manufacturers can achieve intricate designs with unparalleled accuracy, leading to high-quality end products.Efficiency is another hallmark of the China Horizontal Knee Milling Machine. With its advanced automation and streamlined workflow, manufacturers can significantly reduce production times and costs. This increased efficiency allows for a higher volume of production while maintaining strict quality standards. By incorporating this milling machine into their operations, manufacturers can optimize their processes, increasing productivity and staying competitive in the global market.Versatility is a crucial aspect of any modern machinery, and the China Horizontal Knee Milling Machine exceeds expectations in this regard. With its adaptable design, this machine can carry out a wide range of milling operations, catering to diverse industry needs. It can handle various materials, including metals, plastics, and composites, making it a versatile tool for manufacturers across multiple sectors. The ability to perform different milling tasks with a single machine offers flexibility and cost-effectiveness, empowering manufacturers to meet varied customer demands.In addition to its remarkable technological features, the China Horizontal Knee Milling Machine is backed by a comprehensive service and support network. The manufacturing company provides extensive training and aftersales support to their customers worldwide, ensuring smooth integration and operation of the machine. This commitment to customer satisfaction has fostered strong relationships with clients, contributing to the global demand for this innovative milling machine.As China's manufacturing prowess continues to surge, the country's advancements in machinery and equipment are driving global industrial transformation. The China Horizontal Knee Milling Machine is a prime example of this, encapsulating the nation's dedication to innovation and excellence. With its precision, efficiency, and versatility, this milling machine is accelerating manufacturing processes, boosting productivity, and enabling manufacturers to push the boundaries of what is possible.In conclusion, the China Horizontal Knee Milling Machine is revolutionizing the manufacturing industry with its technological advancements and superb performance. Manufacturers across various sectors are embracing this innovative equipment and reaping the benefits of its precision, efficiency, and versatility. Backed by a strong service and support network, this milling machine is poised to continue reshaping the global manufacturing landscape, cementing China's place as a leader in technological innovation and industrial progress. With its impact being felt worldwide, it is evident that the China Horizontal Knee Milling Machine is set to play a transformative role in the future of manufacturing.

China Vertical Machining Center Working Manufacturers: Delivering High-Quality Precision and Efficiency

China's Vertical Machining Center Working Manufacturers Focus on Delivering High-Quality Precision MachineryChina has emerged as a global leader in the manufacturing industry, with a strong emphasis on precision machinery. Among the many sectors, the vertical machining center working manufacturers have played a significant role in meeting the growing demand for high-quality machinery. These manufacturers have been pivotal in driving China's industrial growth and increasing its competitiveness in the global market. Let's explore some of the leading vertical machining center working manufacturers in China, their contributions, and their commitment to delivering cutting-edge products.1. Manufacturer A: With decades of experience in the industry, Manufacturer A has established a strong reputation for producing top-notch vertical machining centers. Their machinery is known for its exceptional precision and efficiency, making it an ideal choice for a wide range of industries, including automotive, aerospace, and electronics. The company invests heavily in research and development to stay ahead of the technological curve, ensuring their products are at the forefront of innovation. Moreover, Manufacturer A places great importance on customer satisfaction, offering exceptional after-sales service and support.2. Manufacturer B: Recognized for its commitment to continuous improvement, Manufacturer B has made significant strides in the vertical machining center working industry. They focus on incorporating advanced technologies and manufacturing processes to enhance the performance and reliability of their products. Manufacturer B places a strong emphasis on quality control, implementing strict measures to ensure each machine meets the highest standards. Furthermore, the company has a comprehensive training program for its employees, ensuring they have the necessary skills and expertise to deliver exceptional results.3. Manufacturer C: Known for their expertise in customization, Manufacturer C specializes in tailoring vertical machining centers to suit specific client requirements. They have a dedicated team of engineers who work closely with customers to understand their unique needs and develop tailor-made solutions. Manufacturer C's focus on customization has allowed them to stand out in the market, catering to a diverse range of industries, including medical, telecommunications, and energy. Additionally, the company prioritizes sustainable manufacturing practices, ensuring their machinery is eco-friendly and energy-efficient.4. Manufacturer D: Renowned for their cutting-edge technology, Manufacturer D has made significant contributions to the vertical machining center working industry. They are at the forefront of adopting advanced manufacturing techniques, such as artificial intelligence and robotic automation, to enhance productivity and precision. Manufacturer D's commitment to research and development is evident in their extensive portfolio of patents and innovative designs. The company also places great importance on fostering partnerships with leading academic institutions and industry experts to stay abreast of the latest advancements.In conclusion, China's vertical machining center working manufacturers have made remarkable progress in delivering high-quality precision machinery. Their commitment to research and development, quality control, customization, and technological innovation has positioned China as a global leader in this industry. Customers worldwide can trust these manufacturers to provide cutting-edge vertical machining centers that meet their unique needs. As the demand for precision machinery continues to grow, these manufacturers are poised to play a crucial role in shaping the future of the manufacturing industry.

5-Axis CNC Machine: The Latest Advancement in Gantry Technology

[Company Name], a leading manufacturer of precision engineering solutions, has recently unveiled their latest innovation in CNC technology - the Gantry 5 Axis CNC Machine. This state-of-the-art machine promises to revolutionize the manufacturing industry with its advanced capabilities and unmatched precision.The Gantry 5 Axis CNC Machine is a powerful and versatile tool that is designed to handle a wide range of machining tasks with incredible speed and accuracy. Equipped with five axes of motion, this machine is capable of performing complex machining operations on large and cumbersome workpieces with ease. Whether it's milling, drilling, or cutting, the Gantry 5 Axis CNC Machine can handle it all with exceptional efficiency.One of the most impressive features of this machine is its gantry design, which provides superior stability and rigidity during the machining process. This means that even when working on heavy and demanding materials, the Gantry 5 Axis CNC Machine can maintain its precision and produce high-quality results every time. This level of reliability is crucial for industries such as aerospace, automotive, and defense, where the smallest error can have significant consequences.Moreover, the Gantry 5 Axis CNC Machine is equipped with advanced software and control systems that allow for seamless integration with CAD/CAM programs, enabling precise and accurate machining based on digital designs. This not only reduces the risk of human error but also shortens the production cycle, leading to faster turnaround times and increased productivity for manufacturers.In addition, [Company Name]'s Gantry 5 Axis CNC Machine is built with the latest cutting-edge technology, including high-performance spindles, tool changers, and automatic workpiece measurement systems. These features not only contribute to the machine's exceptional performance but also make it incredibly user-friendly, requiring minimal manual intervention and maintenance.[Company Name] has a strong track record of delivering innovative and reliable engineering solutions to a wide range of industries. Their dedication to pushing the boundaries of technology and their commitment to quality and precision have earned them a solid reputation in the manufacturing world.With the introduction of the Gantry 5 Axis CNC Machine, [Company Name] further cements its position as a leader in the field of advanced machining solutions. This machine represents a significant leap forward in CNC technology and is poised to set new standards for precision and efficiency in the manufacturing industry."We are thrilled to introduce the Gantry 5 Axis CNC Machine to the market," said [Company Name] spokesperson. "We believe that this machine has the potential to transform the way manufacturers approach complex machining tasks. Its unmatched precision and versatility make it an indispensable tool for any industry that demands the highest quality standards."As industries continue to evolve and demand more sophisticated engineering solutions, innovative machines like the Gantry 5 Axis CNC Machine are essential for meeting these challenges. With its exceptional performance and advanced capabilities, this machine is set to make a lasting impact on the manufacturing landscape and is sure to be a game-changer for [Company Name] and its clients.

An Overview of High Precision Machining Center: Benefits and Uses

The High Precision Machining Center has revolutionized the manufacturing industry with its advanced technology and top-notch precision engineering capabilities. This cutting-edge equipment has become an essential tool for companies looking to achieve the highest levels of accuracy and quality in their production processes.With the ability to perform a wide range of machining operations with incredible precision, the High Precision Machining Center has earned a reputation as one of the most advanced and versatile pieces of equipment in the industry. Its remarkable accuracy and efficiency have made it a valuable asset for a diverse range of industries, including aerospace, automotive, electronics, and medical device manufacturing.The High Precision Machining Center is equipped with state-of-the-art technology that allows for ultra-precise cutting, milling, drilling, and turning operations. Its advanced control systems and high-speed spindles ensure that every machined part meets the strictest tolerance requirements, resulting in superior quality and consistency.One of the key features of the High Precision Machining Center is its ability to handle complex and intricate geometries with ease. This level of precision and versatility allows manufacturers to produce a wide variety of components and parts with the utmost accuracy, regardless of their complexity or intricacy.In addition to its incredible precision, the High Precision Machining Center also offers unmatched efficiency and productivity. Its high-speed machining capabilities enable manufacturers to significantly reduce cycle times and increase throughput, leading to greater overall output and improved operational efficiency.Furthermore, the High Precision Machining Center is designed for seamless integration with advanced automation systems, further enhancing its capabilities and allowing for continuous, unmanned operation. This level of automation not only improves production efficiency but also reduces the potential for errors and inconsistencies, ultimately leading to higher-quality finished products.The company behind the High Precision Machining Center, {} has been a leading provider of advanced manufacturing solutions for over [X] years. With a strong focus on innovation and continuous improvement, {} has established itself as a trusted partner for companies looking to stay at the forefront of technological advancements in the industry.{}'s commitment to quality and excellence is evident in the design and performance of the High Precision Machining Center. The company's engineering expertise and rigorous quality control processes ensure that every machine meets the highest standards of performance and reliability, providing manufacturers with the confidence and peace of mind they need to meet their most demanding production requirements.In addition to its superior products, {} is also known for its exceptional customer service and support. The company's team of skilled engineers and technicians are dedicated to helping customers maximize the performance and value of their equipment, providing comprehensive training, technical assistance, and ongoing maintenance services to ensure that every High Precision Machining Center operates at its best for years to come.As the manufacturing industry continues to evolve and demand for high-quality, precision-engineered parts grows, the High Precision Machining Center from {} is poised to play a crucial role in helping companies meet these evolving challenges. With its unmatched precision, efficiency, and reliability, this advanced machining equipment is shaping the future of manufacturing, empowering companies to achieve new levels of success and competitiveness in the global marketplace.In conclusion, the High Precision Machining Center from {} has set a new standard for precision machining and manufacturing excellence. Its advanced technology, exceptional performance, and robust support from {} make it the ideal solution for companies seeking to achieve the highest levels of quality and productivity in their production processes. With its proven track record and ongoing commitment to innovation, {} is poised to remain a leader in the industry, providing cutting-edge solutions that empower manufacturers to thrive in an ever-changing and demanding marketplace.

Advanced CNC Machining Center: The Latest in Precision Manufacturing Technology

CNC Machining Center Revolutionizes Manufacturing at [Company Name][City, State] - [Company Name] is proud to announce the addition of a cutting-edge CNC Machining Center to their manufacturing facility. This state-of-the-art equipment is set to revolutionize the way [Company Name] produces its products, taking their capabilities to new heights and setting them apart as an industry leader.The CNC Machining Center is a versatile and highly efficient piece of equipment that allows for the precise machining of a wide range of materials, including metals, plastics, and composites. It is equipped with advanced technology and features such as multi-axis capabilities, high-speed machining, and automatic tool changers, all of which contribute to its unmatched precision and efficiency.With the addition of this CNC Machining Center, [Company Name] is now able to take on more complex and intricate projects, as well as increase their overall production capacity. This means that they are better equipped to meet the evolving needs of their customers, while also maintaining the high standards of quality and precision that they are known for.The introduction of this cutting-edge equipment also reflects [Company Name]'s commitment to innovation and staying ahead of the curve in the manufacturing industry. By investing in the latest technology, they are demonstrating their dedication to providing their customers with the best possible products and services, while also driving their own growth and success.In addition to the benefits for [Company Name]'s production capabilities, the CNC Machining Center also brings with it a number of advantages for their employees. The advanced automation and precision of the equipment allows for more streamlined and efficient processes, ultimately leading to a more productive and safer working environment for the team. This aligns with [Company Name]'s ongoing efforts to prioritize the well-being and satisfaction of their employees.Commenting on the addition of the CNC Machining Center, [Company Name] Chief Operating Officer stated, "We are incredibly excited to introduce this new equipment to our manufacturing facility. The capabilities and efficiency of the CNC Machining Center are truly remarkable, and we believe that it will have a significant impact on our ability to deliver top-quality products to our customers. This investment is a testament to our ongoing commitment to innovation and excellence, and we are confident that it will propel us to new heights in the industry."The CNC Machining Center is already up and running at [Company Name]'s manufacturing facility and is expected to make an immediate impact on their production capabilities. As they continue to explore the full potential of this cutting-edge equipment, [Company Name] is excited to see the positive effects it will have on their business, their customers, and the industry as a whole.About [Company Name]:[Company Name] is a leading manufacturer of [products or services]. With a commitment to quality, innovation, and customer satisfaction, they have established themselves as a trusted partner for businesses across a wide range of industries. By investing in the latest technology and continuously improving their processes, [Company Name] remains at the forefront of the manufacturing industry, delivering exceptional products and solutions to their customers.

Top Small Vertical Machining Center Manufacturer in China

China Small Vertical Machining Center Manufacturer Leads the Industry with Advanced Technology and PrecisionAs a leading manufacturer of small vertical machining centers in China, [company name] has been making waves in the industry with its cutting-edge technology and commitment to precision engineering. With a track record of delivering high-quality products, the company has positioned itself as a game-changer in the field of machining center manufacturing.Established in [year], [company name] has quickly emerged as a force to be reckoned with in the industry. The company's state-of-the-art manufacturing facility is equipped with the latest machinery and tools, ensuring that every small vertical machining center that rolls off the production line meets the highest standards of quality. From design and development to production and testing, [company name] maintains strict quality control measures at every stage of the manufacturing process.One of the key factors driving the success of [company name] is its relentless focus on innovation. The company continuously invests in research and development to stay ahead of the curve and incorporate the latest technological advancements into its products. By leveraging cutting-edge technology, [company name] is able to produce small vertical machining centers that offer unparalleled precision, efficiency, and reliability.In addition to its technological prowess, [company name] takes pride in its team of highly skilled engineers and technicians who bring a wealth of expertise and experience to the table. The company's commitment to recruiting and retaining top talent has enabled it to push the boundaries of innovation and deliver superior products that exceed customer expectations.Furthermore, [company name] places a strong emphasis on customer satisfaction. By understanding the unique needs of its clients, the company is able to tailor its small vertical machining centers to meet specific requirements and deliver bespoke solutions. Whether it's the automotive, aerospace, medical, or any other industry, [company name] has the capabilities to cater to a diverse range of applications and provide customized machining solutions.With a strong foothold in the domestic market, [company name] has also been actively expanding its presence on the global stage. The company's small vertical machining centers have gained traction in international markets, winning over customers with their superior performance and reliability. By forging strategic partnerships and collaborations, [company name] is steadily making inroads into new territories and establishing itself as a trusted name in the global machining center industry.Looking ahead, [company name] remains committed to pushing the boundaries of innovation and setting new benchmarks for excellence in small vertical machining center manufacturing. By staying at the forefront of technological advancements and continuously raising the bar for quality, the company is poised to lead the industry into a new era of precision engineering.In conclusion, [company name] is a trailblazer in the field of small vertical machining center manufacturing, setting new standards for quality, innovation, and customer satisfaction. With its unwavering commitment to excellence and a forward-looking approach to technology, the company is primed to continue making waves in the industry and cementing its reputation as a global leader in precision engineering.